EBOOK - Assembly Processes - Finishing Packaging and Automation (Richard Crowson)

EBOOK - Quy trình lắp ráp, đóng gói và tự động hóa (Richard Crowson) - 169 Trang.

The final book, Volume IV, deals with the finishing of the product. Packaging and automation are also discussed. The selection of the assembly process and the influence of production rate and quality of the product must be considered by the manufacturing engineer as the productivity of the facility and workers is balanced.

Jack M. Walker, who was unable to participate in the editing of this book, but who contributed greatly in the last few months of his life, was a pioneer in new ways of solving old problems.

Chapter 1 Manual Assembly 1

John P. Tanner and Jack M. Walker

1.0 Introduction to Manual Assembly 1

1.1 Assembly Work Instructions 4

1.2 Assembly Operation Sequences 5

1.3 Workstation and Line Layout 11

1.4 Manufacturing Methods Analysis 12

1.5 Principles of Motion Economy 20

1.6 Standard Manufacturing Processes 26

1.7 Special Manufacturing Instructions 28

References 29

Chapter 2 Assembly Automation 31

Jack M. Walker and Vijay Sheth

2.1 Introduction to Assembly Automation 31

2.2 Assembly Machines in the Factory 32

2.3 Basic Automation Concepts 32

2.4 Types of Automated Assembly Machines 33

2.5 Motion Systems 38

2.6 Justifying Automation 44

2.7 Software Interfaces to Assembly Automation 48

2.8 Design for Automated Production 49

2.9 Automated Material Handling 57

References 72

Chapter 3 Electronics Assembly 73

Michael Pecht, Denise Burkus Harris and Shrikar Bhagath

3.1 Introduction to Electronics Assembly 73

3.2 Typical Package Architecture 74

3.3 Elementary Subassemblies 74

3.4 Chip Carrier Assemblies 91

3.5 Hybrid Microelectronics Assemblies 95

3.6 Printed Wiring Board Assemblies 122

3.7 System Integration 142

References 144

Suggested Readings 144

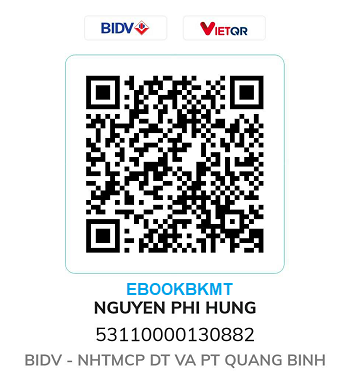

LINK DOWNLOAD

EBOOK - Quy trình lắp ráp, đóng gói và tự động hóa (Richard Crowson) - 169 Trang.

The final book, Volume IV, deals with the finishing of the product. Packaging and automation are also discussed. The selection of the assembly process and the influence of production rate and quality of the product must be considered by the manufacturing engineer as the productivity of the facility and workers is balanced.

Jack M. Walker, who was unable to participate in the editing of this book, but who contributed greatly in the last few months of his life, was a pioneer in new ways of solving old problems.

Chapter 1 Manual Assembly 1

John P. Tanner and Jack M. Walker

1.0 Introduction to Manual Assembly 1

1.1 Assembly Work Instructions 4

1.2 Assembly Operation Sequences 5

1.3 Workstation and Line Layout 11

1.4 Manufacturing Methods Analysis 12

1.5 Principles of Motion Economy 20

1.6 Standard Manufacturing Processes 26

1.7 Special Manufacturing Instructions 28

References 29

Chapter 2 Assembly Automation 31

Jack M. Walker and Vijay Sheth

2.1 Introduction to Assembly Automation 31

2.2 Assembly Machines in the Factory 32

2.3 Basic Automation Concepts 32

2.4 Types of Automated Assembly Machines 33

2.5 Motion Systems 38

2.6 Justifying Automation 44

2.7 Software Interfaces to Assembly Automation 48

2.8 Design for Automated Production 49

2.9 Automated Material Handling 57

References 72

Chapter 3 Electronics Assembly 73

Michael Pecht, Denise Burkus Harris and Shrikar Bhagath

3.1 Introduction to Electronics Assembly 73

3.2 Typical Package Architecture 74

3.3 Elementary Subassemblies 74

3.4 Chip Carrier Assemblies 91

3.5 Hybrid Microelectronics Assemblies 95

3.6 Printed Wiring Board Assemblies 122

3.7 System Integration 142

References 144

Suggested Readings 144

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

%20(1).png)

Không có nhận xét nào: