EBOOK - Converter Applications and their Influence on Large Electrical Machines - Lecture Notes in Electrical Engineering (Oliver Drubel)

Converter driven applications are applied in more and more processes. Almost any

installed wind-farm, ship drives, steel mills, several boiler feed water pumps, extruder and many other applications operate much more efficient and economic in case of variable speed solutions.

The boundary conditions for a motor will change, if it is supplied by a converter. An electrical machine, which is operated by a converter, can no longer be regarded as an independent component, but is embedded in a system consisting of converter and motor.

An overview of existing converter designs for large electrical machines will be given and methods for the appropriate calculation of machine phenomena, which are implied by converters, will be derived. In the power range above 500 kVA a wide variety of converter types exists. Either diode rectifiers as well as voltage source converters are dominant converter types in several applications.

Additionally cyclo-converters and other current source inverters are still applied in some niche markets. The converter design is different for the individual converter types as well. Voltage source inverters are built f.i. as two-, three- or multi-level converters.

The explanation of the individual phenomena is analysed either on machine converter systems, where a phenomena is especially distinct, or for the most dominant onverter machine combinations within the market. In wide industrial segments the asynchronous machine supplied by a voltage source converter is this dominant system. Nevertheless shaft voltages can be excellently investigated on large turbo-generators with load commutated current source inverters (LCI).

Due to the converter inherent higher voltage harmonics and pulse frequencies special phenomena are caused inside the machine. These phenomena can be the reason for malfunction. Additional losses create additional temperature increases or voltage peaks mean higher stress levels for the insulation. Torque ripple can occur, which endanger the mechanical shaft system and last but not least shaft voltages are induced, which are sometimes sufficient in amplitude to damage bearings or to disturb sensors of the protection arrangements.

Variable speed means also, that effects, which would be related to the grid frequency for direct on line applications, will occur for a variable fundamental frequency. Electromagnetic forces, which act as source for noise, will be activated with variable frequencies. Eigen-modes, which have not been excited from the grid frequency, may be dominant due to resonance effects at converter imposed speeds. Direct on line machines can be operated at low damped over-critical speeds, if the distance to the closest critical speed is for instance 15 %-20 % of the rated speed. In a variable speed application this constraint is not sufficient.

Low damped critical speeds should not occur within the complete speed control range and 15 %-20 % beside of it.

Last but not least two typical converter applications will be analyzed, which are typical for most of the converter applications. Both have certain relevance for the global warming. Converter pump drives will contribute towards energy efficiency in a system and the consideration of efficiencies in steel mill applications means a real challenge regarding their overload requirements.

Most chapters are based on the authors’ industrial experience in combination with available literature. Deep investigations in insulation systems are important to design a machine, which is appropriatefor converter applications. Due to the authors’ lack of experience in this area, chapter 8 is based strongly on the work from Dr. Kaufhold, [8.5].

The work on this book lasted several years. Several people supported me during this time in different ways. Prof. S. Kulig motivated me to start at all. He created the awareness of a scientific harbor in Dortmund, where it is possible to get support and new ideas at any time.

EspeciallyDr. S. Exnowski led me through the labyrinth of numeric structure dynamic calculations for the chapter of noise. The final version of the thesis is the result of the dedicated encouragement from Prof. W. Hofmann in reviewing and discussion on individual topics. Prof. K. Reichert and Prof. A. Lindemann took over the second review. I am very conscious of the support, which I received from several colleagues in Birr and Nürnberg.

I want especially to thank K. Bauer for the voltage measurements, as well as H. Kleinod and Dr. C. Mundo for the good will, with which my scientific “hobby” was looked at. Last but not least I am in debt to my family Perrine, Lara and Pierre for their patience during the last years.

Converter driven applications are applied in more and more processes. Almost any installed wind-farm, ship drives, steel mills, several boiler feed water pumps, extruder and many other applications operate much more efficient and economic in case of variable speed solutions. The boundary conditions for a motor will change, if it is supplied by a converter. An electrical machine, which is operated by a converter, can no longer be regarded as an independent component, but is embedded in a system consisting of converter and motor.

An overview of existing converter designs for large electrical machines will be given and methods for the appropriate calculation of machine phenomena, which are implied by converters, will be derived. In the power range above 500 kVA a wide variety of converter types exists. Either diode rectifiers as well as voltage source converters are dominant converter types in several applications.

Additionally cyclo-converters and other current source inverters are still applied in some niche markets. The converter design is different for the individual converter types as well. Voltage source inverters are built f.i. as two-, three- or multi-level converters. The explanation of the individual phenomena is analysed either on machine converter systems, where a phenomena is especially distinct, or for the most dominant converter machine combinations within the market. In wide industrial segments the asynchronous machine supplied by a voltage source converter is this

dominant system.

Nevertheless shaft voltages can be excellently investigated on large turbo-generators with load commutated current source inverters (LCI). Due to the converter inherent higher voltage harmonics and pulse frequencies special phenomena are caused inside the machine. These phenomena can be the reason for malfunction. Additional losses create additional temperature increases or voltage peaks mean higher stress levels for the insulation.

Torque ripple can occur, which endanger the mechanical shaft system and last but not least shaft voltages are induced, which are sometimes sufficient in amplitude to damage bearings or to disturb sensors of the protection arrangements.

Variable speed means also, that effects, which would be related to the grid frequency for direct on line applications, will occur for a variable fundamental frequency. Electromagnetic forces, which act as source for noise, will be activated with variable frequencies. Eigen-modes, which have not been excited from the grid frequency, may be dominant due to resonance effects at converter imposed speeds. Direct on line machines can be operated at low damped over-critical speeds, if the distance to the closest critical speed is for instance 15 %-20 % of the rated speed. In a variable speed application this constraint is not sufficient. Low damped critical speeds should not occur within the complete speed control range and 15 %-20 % beside of it.

Last but not least two typical converter applications will be analyzed, which are typical for most of the converter applications. Both have certain relevance for the global warming. Converter pump drives will contribute towards energy efficiency in a system and the consideration of efficiencies in steel mill applications means a real challenge regarding their overload requirements.

Most chapters are based on the authors’ industrial experience in combination with available literature. Deep investigations in insulation systems are important to design a machine, which is appropriatefor converter applications. Due to the authors’ lack of experience in this area, chapter 8 is based strongly on the work from Dr. Kaufhold, [8.5].

The work on this book lasted several years. Several people supported me during this time in different ways. Prof. S. Kulig motivated me to start at all. He created the awareness of a scientific harbor in Dortmund, where it is possible to get support and new ideas at any time. EspeciallyDr. S. Exnowski led me through the labyrinth of numeric structure dynamic calculations for the chapter of noise.

The final version of the thesis is the result of the dedicated encouragement from Prof.

W. Hofmann in reviewing and discussion on individual topics. Prof. K. Reichert and Prof. A. Lindemann took over the second review. I am very conscious of the support, which I received from several colleagues in Birr and Nürnberg. I want especially to thank K. Bauer for the voltage measurements, as well as H. Kleinod and Dr. C. Mundo for the good will, with which my scientific “hobby” was looked at. Last but not least I am in debt to my family Perrine, Lara and Pierre for their patience during the last years.

1 Introduction ...................................................................................................... 1

1.1 Industrial Requirements for Variable Speed Drives and Applications

of Brushless Exciters .................................................................................. 1

1.2 Research Activities in the Field of Large and Medium Size Converter

Drives.......................................................................................................... 5

2 Typical Converter Designs for Electrical Machines ...................................... 9

2.1 Overview of Converters and Their Application .......................................... 9

2.2 Naturally Commutating Converters .......................................................... 10

2.3 Forced Commutating Converters .............................................................. 16

2.4 Harmonic Content in the Voltage and Current Characteristics

of Different Converter Types .................................................................... 22

3 Calculation-Methods for Converter Fed Electrical Machines .................... 27

3.1 Analytical Calculation Methods for Special Operation Points

and Machine Model Integration into Circuits ........................................... 27

3.2 Non-linear Transient Time-Stepping Numerical Field Calculation

with Integrated Circuit Elements .............................................................. 35

4 Additional Losses Due to Higher Voltage Harmonics ................................. 45

4.1 Overview of Converter Dependent Loss Components .............................. 45

4.2 Eddy Current Distribution within the Stator and Rotor Winding ............. 46

4.3 Additional Iron Losses within the Stator and Rotor Lamination .............. 50

4.4 Eddy Current Losses within Massive Magnetic Material ......................... 52

4.5 Loss Measurement within Magnetic Material .......................................... 63

4.6 Additional Losses for Different Voltage Source Converter Types ........... 65

5 Converter Caused Torque Oscillations ......................................................... 69

5.1 Interaction between Stator Field Components .......................................... 69

5.2 Calculation of Electromagnetic Torque Oscillations ................................ 71

5.3 Torsional Shaft Oscillations and Design Rules ......................................... 77

6 Noise Based on ElectromagneticSources in Case of Converter

Operation ......................................................................................................... 85

6.1 General Overview of Noise Calculation ................................................... 85

6.2 Determination of the Electromagnetic Force Modes and Amplitudes ...... 86

X Contents

6.3 Eigen-Modes and Mechanical Calculation Methods ................................ 95

6.4 Influence of Pulse Frequency and Converter Operation on Noise

Phenomena .............................................................................................. 101

7 Converter Caused Shaft Voltages ............................................................... 109

7.1 Overview of Different Shaft Voltage Types ........................................... 109

7.2 Circumferential Flux and Capacitive Imposed Shaft Voltages ............... 110

7.3 Measurements of Current Path and Voltage Transients .......................... 119

7.4 Shaft Grounding and Converter Concepts .............................................. 129

8 Insulation Strategies in Converter Driven Machines ................................ 135

8.1 Overview of Converter Implied Insulation Stress ................................... 135

8.2 Potential Distribution within a Converter Supplied Electrical

Machine .................................................................................................. 136

8.3 Voltage Peaks due to Wave Reflection ................................................... 137

8.4 Influence of the Voltage Characteristic on the Insulation Life Time ...... 141

8.5 Influence of the Converter Type on the Insulation System ..................... 149

9 Converter Applications in Typical Examples of Energy Efficient Pump

Systems and in Processes with a Strong Overload Characteristic ............ 153

9.1 Energy Saving Potential for Boiler Feed Water Pumps in Part Load

Operated Coal Power Plants for Different Drive Arrangements ............. 153

9.2 Influence of Speed and Overload Capability of Steel Mill Drives

on the Motor Efficiency .......................................................................... 158

10 Conclusion ................................................................................................... 161

Attachment ......................................................................................................... 165

A.1 Parameters of Asynchronous Machines ................................................. 165

A.2 Parameters of Synchronous Machines ................................................... 168

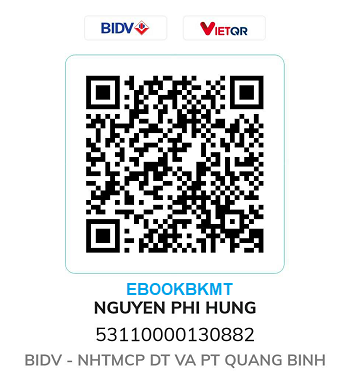

LINK DOWNLOAD

Converter driven applications are applied in more and more processes. Almost any

installed wind-farm, ship drives, steel mills, several boiler feed water pumps, extruder and many other applications operate much more efficient and economic in case of variable speed solutions.

The boundary conditions for a motor will change, if it is supplied by a converter. An electrical machine, which is operated by a converter, can no longer be regarded as an independent component, but is embedded in a system consisting of converter and motor.

An overview of existing converter designs for large electrical machines will be given and methods for the appropriate calculation of machine phenomena, which are implied by converters, will be derived. In the power range above 500 kVA a wide variety of converter types exists. Either diode rectifiers as well as voltage source converters are dominant converter types in several applications.

Additionally cyclo-converters and other current source inverters are still applied in some niche markets. The converter design is different for the individual converter types as well. Voltage source inverters are built f.i. as two-, three- or multi-level converters.

The explanation of the individual phenomena is analysed either on machine converter systems, where a phenomena is especially distinct, or for the most dominant onverter machine combinations within the market. In wide industrial segments the asynchronous machine supplied by a voltage source converter is this dominant system. Nevertheless shaft voltages can be excellently investigated on large turbo-generators with load commutated current source inverters (LCI).

Due to the converter inherent higher voltage harmonics and pulse frequencies special phenomena are caused inside the machine. These phenomena can be the reason for malfunction. Additional losses create additional temperature increases or voltage peaks mean higher stress levels for the insulation. Torque ripple can occur, which endanger the mechanical shaft system and last but not least shaft voltages are induced, which are sometimes sufficient in amplitude to damage bearings or to disturb sensors of the protection arrangements.

Variable speed means also, that effects, which would be related to the grid frequency for direct on line applications, will occur for a variable fundamental frequency. Electromagnetic forces, which act as source for noise, will be activated with variable frequencies. Eigen-modes, which have not been excited from the grid frequency, may be dominant due to resonance effects at converter imposed speeds. Direct on line machines can be operated at low damped over-critical speeds, if the distance to the closest critical speed is for instance 15 %-20 % of the rated speed. In a variable speed application this constraint is not sufficient.

Low damped critical speeds should not occur within the complete speed control range and 15 %-20 % beside of it.

Last but not least two typical converter applications will be analyzed, which are typical for most of the converter applications. Both have certain relevance for the global warming. Converter pump drives will contribute towards energy efficiency in a system and the consideration of efficiencies in steel mill applications means a real challenge regarding their overload requirements.

Most chapters are based on the authors’ industrial experience in combination with available literature. Deep investigations in insulation systems are important to design a machine, which is appropriatefor converter applications. Due to the authors’ lack of experience in this area, chapter 8 is based strongly on the work from Dr. Kaufhold, [8.5].

The work on this book lasted several years. Several people supported me during this time in different ways. Prof. S. Kulig motivated me to start at all. He created the awareness of a scientific harbor in Dortmund, where it is possible to get support and new ideas at any time.

EspeciallyDr. S. Exnowski led me through the labyrinth of numeric structure dynamic calculations for the chapter of noise. The final version of the thesis is the result of the dedicated encouragement from Prof. W. Hofmann in reviewing and discussion on individual topics. Prof. K. Reichert and Prof. A. Lindemann took over the second review. I am very conscious of the support, which I received from several colleagues in Birr and Nürnberg.

I want especially to thank K. Bauer for the voltage measurements, as well as H. Kleinod and Dr. C. Mundo for the good will, with which my scientific “hobby” was looked at. Last but not least I am in debt to my family Perrine, Lara and Pierre for their patience during the last years.

Converter driven applications are applied in more and more processes. Almost any installed wind-farm, ship drives, steel mills, several boiler feed water pumps, extruder and many other applications operate much more efficient and economic in case of variable speed solutions. The boundary conditions for a motor will change, if it is supplied by a converter. An electrical machine, which is operated by a converter, can no longer be regarded as an independent component, but is embedded in a system consisting of converter and motor.

An overview of existing converter designs for large electrical machines will be given and methods for the appropriate calculation of machine phenomena, which are implied by converters, will be derived. In the power range above 500 kVA a wide variety of converter types exists. Either diode rectifiers as well as voltage source converters are dominant converter types in several applications.

Additionally cyclo-converters and other current source inverters are still applied in some niche markets. The converter design is different for the individual converter types as well. Voltage source inverters are built f.i. as two-, three- or multi-level converters. The explanation of the individual phenomena is analysed either on machine converter systems, where a phenomena is especially distinct, or for the most dominant converter machine combinations within the market. In wide industrial segments the asynchronous machine supplied by a voltage source converter is this

dominant system.

Nevertheless shaft voltages can be excellently investigated on large turbo-generators with load commutated current source inverters (LCI). Due to the converter inherent higher voltage harmonics and pulse frequencies special phenomena are caused inside the machine. These phenomena can be the reason for malfunction. Additional losses create additional temperature increases or voltage peaks mean higher stress levels for the insulation.

Torque ripple can occur, which endanger the mechanical shaft system and last but not least shaft voltages are induced, which are sometimes sufficient in amplitude to damage bearings or to disturb sensors of the protection arrangements.

Variable speed means also, that effects, which would be related to the grid frequency for direct on line applications, will occur for a variable fundamental frequency. Electromagnetic forces, which act as source for noise, will be activated with variable frequencies. Eigen-modes, which have not been excited from the grid frequency, may be dominant due to resonance effects at converter imposed speeds. Direct on line machines can be operated at low damped over-critical speeds, if the distance to the closest critical speed is for instance 15 %-20 % of the rated speed. In a variable speed application this constraint is not sufficient. Low damped critical speeds should not occur within the complete speed control range and 15 %-20 % beside of it.

Last but not least two typical converter applications will be analyzed, which are typical for most of the converter applications. Both have certain relevance for the global warming. Converter pump drives will contribute towards energy efficiency in a system and the consideration of efficiencies in steel mill applications means a real challenge regarding their overload requirements.

Most chapters are based on the authors’ industrial experience in combination with available literature. Deep investigations in insulation systems are important to design a machine, which is appropriatefor converter applications. Due to the authors’ lack of experience in this area, chapter 8 is based strongly on the work from Dr. Kaufhold, [8.5].

The work on this book lasted several years. Several people supported me during this time in different ways. Prof. S. Kulig motivated me to start at all. He created the awareness of a scientific harbor in Dortmund, where it is possible to get support and new ideas at any time. EspeciallyDr. S. Exnowski led me through the labyrinth of numeric structure dynamic calculations for the chapter of noise.

The final version of the thesis is the result of the dedicated encouragement from Prof.

W. Hofmann in reviewing and discussion on individual topics. Prof. K. Reichert and Prof. A. Lindemann took over the second review. I am very conscious of the support, which I received from several colleagues in Birr and Nürnberg. I want especially to thank K. Bauer for the voltage measurements, as well as H. Kleinod and Dr. C. Mundo for the good will, with which my scientific “hobby” was looked at. Last but not least I am in debt to my family Perrine, Lara and Pierre for their patience during the last years.

1 Introduction ...................................................................................................... 1

1.1 Industrial Requirements for Variable Speed Drives and Applications

of Brushless Exciters .................................................................................. 1

1.2 Research Activities in the Field of Large and Medium Size Converter

Drives.......................................................................................................... 5

2 Typical Converter Designs for Electrical Machines ...................................... 9

2.1 Overview of Converters and Their Application .......................................... 9

2.2 Naturally Commutating Converters .......................................................... 10

2.3 Forced Commutating Converters .............................................................. 16

2.4 Harmonic Content in the Voltage and Current Characteristics

of Different Converter Types .................................................................... 22

3 Calculation-Methods for Converter Fed Electrical Machines .................... 27

3.1 Analytical Calculation Methods for Special Operation Points

and Machine Model Integration into Circuits ........................................... 27

3.2 Non-linear Transient Time-Stepping Numerical Field Calculation

with Integrated Circuit Elements .............................................................. 35

4 Additional Losses Due to Higher Voltage Harmonics ................................. 45

4.1 Overview of Converter Dependent Loss Components .............................. 45

4.2 Eddy Current Distribution within the Stator and Rotor Winding ............. 46

4.3 Additional Iron Losses within the Stator and Rotor Lamination .............. 50

4.4 Eddy Current Losses within Massive Magnetic Material ......................... 52

4.5 Loss Measurement within Magnetic Material .......................................... 63

4.6 Additional Losses for Different Voltage Source Converter Types ........... 65

5 Converter Caused Torque Oscillations ......................................................... 69

5.1 Interaction between Stator Field Components .......................................... 69

5.2 Calculation of Electromagnetic Torque Oscillations ................................ 71

5.3 Torsional Shaft Oscillations and Design Rules ......................................... 77

6 Noise Based on ElectromagneticSources in Case of Converter

Operation ......................................................................................................... 85

6.1 General Overview of Noise Calculation ................................................... 85

6.2 Determination of the Electromagnetic Force Modes and Amplitudes ...... 86

X Contents

6.3 Eigen-Modes and Mechanical Calculation Methods ................................ 95

6.4 Influence of Pulse Frequency and Converter Operation on Noise

Phenomena .............................................................................................. 101

7 Converter Caused Shaft Voltages ............................................................... 109

7.1 Overview of Different Shaft Voltage Types ........................................... 109

7.2 Circumferential Flux and Capacitive Imposed Shaft Voltages ............... 110

7.3 Measurements of Current Path and Voltage Transients .......................... 119

7.4 Shaft Grounding and Converter Concepts .............................................. 129

8 Insulation Strategies in Converter Driven Machines ................................ 135

8.1 Overview of Converter Implied Insulation Stress ................................... 135

8.2 Potential Distribution within a Converter Supplied Electrical

Machine .................................................................................................. 136

8.3 Voltage Peaks due to Wave Reflection ................................................... 137

8.4 Influence of the Voltage Characteristic on the Insulation Life Time ...... 141

8.5 Influence of the Converter Type on the Insulation System ..................... 149

9 Converter Applications in Typical Examples of Energy Efficient Pump

Systems and in Processes with a Strong Overload Characteristic ............ 153

9.1 Energy Saving Potential for Boiler Feed Water Pumps in Part Load

Operated Coal Power Plants for Different Drive Arrangements ............. 153

9.2 Influence of Speed and Overload Capability of Steel Mill Drives

on the Motor Efficiency .......................................................................... 158

10 Conclusion ................................................................................................... 161

Attachment ......................................................................................................... 165

A.1 Parameters of Asynchronous Machines ................................................. 165

A.2 Parameters of Synchronous Machines ................................................... 168

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

Không có nhận xét nào: