EBOOK - Production Chemicals for the Oil and Gas Industry (Malcolm A. Kelland)

I would like to thank those of you who bought the first edition. I hope you found it helpful. Thanks also to those who gave me feedback, nearly all of which was positive and was encouragement enough to provide you with this update.

This second edition contains literature references up until autumn 2013. Even though this is only 4.5 years since the first edition, a huge amount of research and field applications have taken place since then. For example, the number of references in this book has increased by almost 50%, almost none of which pre-date 2009. Other changes and trends I have observed within the development of oilfield production chemicals I have reported (M.A. Kelland, “Production Chemicals and Their Future,” Chemistry in the Oil Industry XIII—New Frontiers, Manchester, UK, November 2013).

For easy location of new articles, all new references are added numerically after the list of references from the first edition. For example, in Chapter 1, references 1–54 are from the first edition and references 55–96 are added to the second edition.

So, apart from updating each chapter, what’s new in this second edition? First, I have expanded and separated out the section on foamers for gas well deliquification and given this subject its own chapter (Chapter 19). I have also included a new chapter (Chapter 18) on hydrotesting, as requested by a number of you. In addition, I have added a section on chemical injection in Chapter 1. These new additions are undoubtedly not exhaustive, so I would welcome your feedback on these. I have

also been asked to add other chapters, such as surfactant and/or polymer flooding for enhanced oil recovery, heavy oil transportation, fracturing fluids, and tracers. Owing to size constraints by the publisher and my own time constraints, I have not been able to add these other topics.

Chapter 1 Introduction and Environmental Issues........................................................................1

1.1 Production Chemistry Overview .......................................................................1

1.2 Factors That Affect the Choice of Production Chemicals.................................4

1.2.1 Chemical Injection, Where to Inject, and Other Methods of Chemical Deployment

1.2.1.1 What Is the Best Place to Inject the Chemical to Maximize the Efficacy of the Treatment?

1.2.1.2 Will the Chemical Have Enough Residence Time in the Line to Do Its Job Properly?

1.2.1.3 Is the Chemical Compatible with the Temperature at the Injection Site?

1.2.1.4 Is the Chemical Compatible with the Fluids into Which It Is Injected?

1.2.1.5 Will the Chemical Cause Unwanted Side Effects in the Injection, Production, or Processing Equipment?...........8

1.2.1.6 Will the Chemical Affect the Efficacy of Other

Production Chemicals? .........................................................8

1.2.1.7 Viscosity and Pumping Problems in the Injection Line .......9

1.3 Environmental and Ecotoxicological Regulations ............................................9

1.3.1 OSPAR Environmental Regulations for Oilfield Chemicals .............10

1.3.2 European REACH Regulations ..........................................................11

1.3.3 United States Environmental Regulations .........................................12

1.3.4 Environmental Regulations Elsewhere ..............................................12

1.4 Designing Greener Chemicals .........................................................................13

1.4.1 Bioaccumulation .................................................................................13

1.4.2 Reducing Toxicity...............................................................................13

1.4.3 Achieving Biodegradability ...............................................................14

1.5 Mercury and Arsenic Production ....................................................................17

Chapter 2 Water and Gas Control ...............................................................................................23

2.1 Introduction .....................................................................................................23

2.2 Resins and Elastomers .....................................................................................24

2.3 Inorganic Gels .................................................................................................24

2.4 Cross-Linked Organic Polymer Gels for Permanent Shut-Off .......................26

2.4.1 Polymer Injection ...............................................................................26

2.4.1.1 Metal Ion Cross-Linking of Carboxylate-Containing Acrylamides and Biopolymers

2.4.1.2 Gels Using Natural Polymers .............................................28

2.4.1.3 Organic Cross-Linking .......................................................29

2.4.1.4 Polyvinyl Alcohol or Polyvinylamine Gels ........................31

2.4.1.5 Problems Associated with Polymer Gel Water Shut- Off Treatments

2.4.1.6 Other Improvements for Cross-Linked Polymer Gels ........32

2.4.2 In SituMonomer Polymerization .......................................................32

2.5 Viscoelastic Surfactant Gels ............................................................................33

2.6 Disproportionate Permeability Reducer or Relative Permeability Modifier .......33

2.6.1 Emulsified Gels as DPRs ....................................................................34

2.6.2 Hydrophilic Polymers as RPMs .........................................................34

2.6.2.1 Types of Polymer RPM .......................................................35

2.6.2.2 Hydrophobically Modified Synthetic Polymers as RPMs .....36

2.6.2.3 Cross-Linked Polymer RPMs .............................................38

2.6.2.4 Viscoelastic RPMs ..............................................................39

2.7 Water Control Using Microparticles ...............................................................39

2.8 Thermally Sensitive Water-Soluble Polymers .................................................40

2.9 Water-Swellable Polymers ...............................................................................40

Chapter 3 Scale Control ..............................................................................................................51

3.1 Introduction .....................................................................................................51

3.2 Types of Scale ..................................................................................................51

3.2.1 Calcium Carbonate Scale ...................................................................52

3.2.2 Sulfate Scales .....................................................................................53

3.2.3 Sulfide Scales .....................................................................................54

3.2.4 Sodium Chloride (Halite) Scale .........................................................54

3.2.5 Mixed Scales ......................................................................................55

3.3 Nonchemical Scale Control .............................................................................55

3.4 Scale Inhibition of Group II Carbonates and Sulfates ....................................56

3.4.1 Polyphosphates ...................................................................................58

3.4.2 Phosphate Esters .................................................................................58

3.4.3 Nonpolymeric Phosphonates and Aminophosphonates .....................59

3.4.4 Polyphosphonates ...............................................................................62

3.4.5 Phosphino Polymers and Polyphosphinates .......................................63

3.4.6 Polycarboxylates .................................................................................65

3.4.6.1 Biodegradable Polycarboxylates .........................................66

3.4.7 Polysulfonates .....................................................................................68

3.5 Sulfide Scale Inhibition ...................................................................................69

3.6 Halite Scale Inhibition .....................................................................................70

3.7 Methods of Deploying Scale Inhibitors ...........................................................71

3.7.1 Continuous Injection ..........................................................................72

3.7.2 Scale Inhibitor Squeeze Treatments ...................................................72

3.7.2.1 Scale Inhibitor Squeeze Treatments Combined with Other Well Treatments

3.7.3 Nonaqueous or Solid Scale Inhibitors for Squeeze Treatments .........78

3.7.3.1 Oil-Miscible Scale Inhibitors ..............................................78

3.7.3.2 Totally Water-Free Scale Inhibitors in Organic Solvent Bends

3.7.3.3 Emulsified Scale Inhibitors .................................................79

......

Hóa chất sản xuất cho các ngành công nghiệp dầu khí - Tác giả: Malcolm A. Kelland (432 Trang).

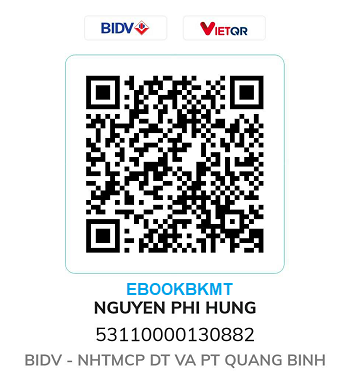

LINK DOWNLOAD

I would like to thank those of you who bought the first edition. I hope you found it helpful. Thanks also to those who gave me feedback, nearly all of which was positive and was encouragement enough to provide you with this update.

This second edition contains literature references up until autumn 2013. Even though this is only 4.5 years since the first edition, a huge amount of research and field applications have taken place since then. For example, the number of references in this book has increased by almost 50%, almost none of which pre-date 2009. Other changes and trends I have observed within the development of oilfield production chemicals I have reported (M.A. Kelland, “Production Chemicals and Their Future,” Chemistry in the Oil Industry XIII—New Frontiers, Manchester, UK, November 2013).

For easy location of new articles, all new references are added numerically after the list of references from the first edition. For example, in Chapter 1, references 1–54 are from the first edition and references 55–96 are added to the second edition.

So, apart from updating each chapter, what’s new in this second edition? First, I have expanded and separated out the section on foamers for gas well deliquification and given this subject its own chapter (Chapter 19). I have also included a new chapter (Chapter 18) on hydrotesting, as requested by a number of you. In addition, I have added a section on chemical injection in Chapter 1. These new additions are undoubtedly not exhaustive, so I would welcome your feedback on these. I have

also been asked to add other chapters, such as surfactant and/or polymer flooding for enhanced oil recovery, heavy oil transportation, fracturing fluids, and tracers. Owing to size constraints by the publisher and my own time constraints, I have not been able to add these other topics.

Chapter 1 Introduction and Environmental Issues........................................................................1

1.1 Production Chemistry Overview .......................................................................1

1.2 Factors That Affect the Choice of Production Chemicals.................................4

1.2.1 Chemical Injection, Where to Inject, and Other Methods of Chemical Deployment

1.2.1.1 What Is the Best Place to Inject the Chemical to Maximize the Efficacy of the Treatment?

1.2.1.2 Will the Chemical Have Enough Residence Time in the Line to Do Its Job Properly?

1.2.1.3 Is the Chemical Compatible with the Temperature at the Injection Site?

1.2.1.4 Is the Chemical Compatible with the Fluids into Which It Is Injected?

1.2.1.5 Will the Chemical Cause Unwanted Side Effects in the Injection, Production, or Processing Equipment?...........8

1.2.1.6 Will the Chemical Affect the Efficacy of Other

Production Chemicals? .........................................................8

1.2.1.7 Viscosity and Pumping Problems in the Injection Line .......9

1.3 Environmental and Ecotoxicological Regulations ............................................9

1.3.1 OSPAR Environmental Regulations for Oilfield Chemicals .............10

1.3.2 European REACH Regulations ..........................................................11

1.3.3 United States Environmental Regulations .........................................12

1.3.4 Environmental Regulations Elsewhere ..............................................12

1.4 Designing Greener Chemicals .........................................................................13

1.4.1 Bioaccumulation .................................................................................13

1.4.2 Reducing Toxicity...............................................................................13

1.4.3 Achieving Biodegradability ...............................................................14

1.5 Mercury and Arsenic Production ....................................................................17

Chapter 2 Water and Gas Control ...............................................................................................23

2.1 Introduction .....................................................................................................23

2.2 Resins and Elastomers .....................................................................................24

2.3 Inorganic Gels .................................................................................................24

2.4 Cross-Linked Organic Polymer Gels for Permanent Shut-Off .......................26

2.4.1 Polymer Injection ...............................................................................26

2.4.1.1 Metal Ion Cross-Linking of Carboxylate-Containing Acrylamides and Biopolymers

2.4.1.2 Gels Using Natural Polymers .............................................28

2.4.1.3 Organic Cross-Linking .......................................................29

2.4.1.4 Polyvinyl Alcohol or Polyvinylamine Gels ........................31

2.4.1.5 Problems Associated with Polymer Gel Water Shut- Off Treatments

2.4.1.6 Other Improvements for Cross-Linked Polymer Gels ........32

2.4.2 In SituMonomer Polymerization .......................................................32

2.5 Viscoelastic Surfactant Gels ............................................................................33

2.6 Disproportionate Permeability Reducer or Relative Permeability Modifier .......33

2.6.1 Emulsified Gels as DPRs ....................................................................34

2.6.2 Hydrophilic Polymers as RPMs .........................................................34

2.6.2.1 Types of Polymer RPM .......................................................35

2.6.2.2 Hydrophobically Modified Synthetic Polymers as RPMs .....36

2.6.2.3 Cross-Linked Polymer RPMs .............................................38

2.6.2.4 Viscoelastic RPMs ..............................................................39

2.7 Water Control Using Microparticles ...............................................................39

2.8 Thermally Sensitive Water-Soluble Polymers .................................................40

2.9 Water-Swellable Polymers ...............................................................................40

Chapter 3 Scale Control ..............................................................................................................51

3.1 Introduction .....................................................................................................51

3.2 Types of Scale ..................................................................................................51

3.2.1 Calcium Carbonate Scale ...................................................................52

3.2.2 Sulfate Scales .....................................................................................53

3.2.3 Sulfide Scales .....................................................................................54

3.2.4 Sodium Chloride (Halite) Scale .........................................................54

3.2.5 Mixed Scales ......................................................................................55

3.3 Nonchemical Scale Control .............................................................................55

3.4 Scale Inhibition of Group II Carbonates and Sulfates ....................................56

3.4.1 Polyphosphates ...................................................................................58

3.4.2 Phosphate Esters .................................................................................58

3.4.3 Nonpolymeric Phosphonates and Aminophosphonates .....................59

3.4.4 Polyphosphonates ...............................................................................62

3.4.5 Phosphino Polymers and Polyphosphinates .......................................63

3.4.6 Polycarboxylates .................................................................................65

3.4.6.1 Biodegradable Polycarboxylates .........................................66

3.4.7 Polysulfonates .....................................................................................68

3.5 Sulfide Scale Inhibition ...................................................................................69

3.6 Halite Scale Inhibition .....................................................................................70

3.7 Methods of Deploying Scale Inhibitors ...........................................................71

3.7.1 Continuous Injection ..........................................................................72

3.7.2 Scale Inhibitor Squeeze Treatments ...................................................72

3.7.2.1 Scale Inhibitor Squeeze Treatments Combined with Other Well Treatments

3.7.3 Nonaqueous or Solid Scale Inhibitors for Squeeze Treatments .........78

3.7.3.1 Oil-Miscible Scale Inhibitors ..............................................78

3.7.3.2 Totally Water-Free Scale Inhibitors in Organic Solvent Bends

3.7.3.3 Emulsified Scale Inhibitors .................................................79

......

Hóa chất sản xuất cho các ngành công nghiệp dầu khí - Tác giả: Malcolm A. Kelland (432 Trang).

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

Không có nhận xét nào: