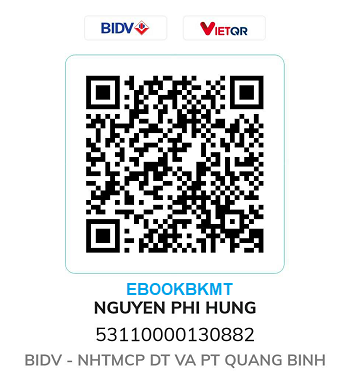

VIP - LIST TÀI LIỆU HỖ TRỢ RIÊNG BỞI GROUP EBOOKBKMT (UPDATE LIÊN TỤC)

LIST TECHNICAL DOCUMENTS SUPPORTED PRIVATE BY GROUP EBOOKBKMT (UPDATE CONTINUOUS ...)

Các tài liệu này do vấn đề liên quan đến bản quyền được thông báo từ các chủ sở hữu nên EBOOKBKMT sẽ không đăng tải lên thư viên.

Các bạn liên hệ qua Group hoặc Inbox Page EBOOKBKMT để nhận link tải cá nhân cho các tài liệu có tên theo list ở bên dưới.

LINK DOWNLOAD EBOOK >>> CONTACT GROUP EBOOKBKMT

- Water and Wastewater Conveyance Pumping Hydraulics Piping and Valves (Frank R. Spellman)

- How Psychology Works Applied Psychology Visually Explained (DK, Jo Hemmings)

- Beginning DirectX 9 (Wendy Jones - Vngamedev)

- Beginning DirectX 9 - Wendy Jones

- Engineering Analysis with SOLIDWORKS Simulation 2018 - Paul M Kurowski

- Mechanical Fastening Joining and Assembly 2nd Edition (James A. Speck)

- Safety Management near Miss Identification Recognition and Investigation (Ron C. McKinnon)

- Transformer Engineering Design Technology and Diagnostics 2nd Edition (S. V. Kulkarni and S. A. Khaparde)

- Aging Power Delivery Infrastructures 2 Ed (H. Lee Willis & Randall R. Schrieber)

- Compressor handbook principles and practice (Tony Giampaolo)

- Fundamentals of Geotechnical Engineering (Braja M. Das)

- Environmental degradation of advanced and traditional engineering materials (Lloyd H. Hihara)

- Handbook of Automotive Power Electronics and Motor Drives (Ali Emadi)

- The Gas Turbine Handbook - Principles and Practices (Tony Giampaolo & Anthony J. Giampaolo)

- Advanced automotive fault diagnosis (Tom Denton)

- Welding for arts & crafts (Dewayne Roy)

- Digital Design and Verilog HDL Fundamentals (Joseph Cavanagh)

- A First Course in the Finite Element Method (Daryl L. Logan)

- Power Vacuum Tubes Handbook Third Edition (Electronics Handbook Series) - Jerry Whitaker

- Analysis of Synchronous Machines Second Edition (T.A. Lipo)

- Engineering Design Process (Yousef Haik & Tamer M. Shahin)

- Essential DC/DC Converters (Fang Lin Luo)

- Vibration Problems in Machines - Diagnosis and Resolution (Arthur W. Lees)

- Ductile Design of Steel Structures (Michel Bruneau & Chia-Ming Uang & Rafael Sabelli)

- The Mechatronics Handbook - Cơ điện tử Tập 1 (Robert H. Bishop - Phạm Anh Tuấn Bd)

- The mechatronics handbook (Robert H. Bishop)

- Beginning DirectX 9 (Wendy Jones - Vngamedev Biên dịch)

- Stability Design of Steel Frames (W. F. Chen & E. M. Lui)

- Planning and Installing Solar Thermal Systems - A Guide for Installers Architects and Engineers (Dgs)

- Synchronous Generators 2 Ed (Ion Boldea)

- English for business communication - Student's book (Simon Sweeney) - PREVIEW

- Professional English in Use - Law (Gillian D. Brown, Sally Rice)

- Modern electric, hybrid electric, and fuel cell vehicles: fundamentals, theory, and design - Mehrdad Ehsani , Yimin Gao , Sebastien E. Gay , Ali Emadi

- Water Wells and Pumps (A. M. Michael & S. D. Khepar & S. K. Sondhi)

- Optical Fiber Sensors Advanced Techniques and Applications (Ginu Rajan)

- Audio Engineer's Reference Book 2nd edition (Michael Talbot - Smith)

- Thermodynamics and Heat Power Eighth Edition (Irving Granet)

- Flight Vehicle Aerodynamics (Mark Drela)

- Boilers for power and process (Kumar Rayaprolu)

- Introduction to Microsystem Packaging Technology (Yufeng Jin)

- Handbook of Research for Mechanical Engineering - Applied Research in Hydraulics and Heat Flow (Kaveh Hariri Asli)

- Materials Handbook (George Stuart Brady & Henry R. Clauser & John A. Vaccari)

- Troubleshooting and Repairing Commercial Electrical Equipment (David Herres)

- Cybersecurity for Industrial Control Systems SCADA, DCS, PLC, HMI, and SIS - Tyson Macaulay, Bryan L.Singer

- Audio Power Amplifier Design Handbook - Third edition (Douglas Self)

- Mechanical Design of Electric Motors (Wei Tong)

- Alternative Energy Technologies - An Introduction with Computer Simulations (Gavin Buxton)

- Air Conditioning - A practical introduction - Third edition (David V. Chadderton)

- Improving Concrete Quality (Karthikeyan H. Obla)

- The Principles of Thermodynamics (N. D. Hari Dass)

- Optical Imaging Devices - New Technologies and Applications (Ajit Khosla & Dongsoo Kim)

- Automotive computer controlled systems (Allan Bonnick)

- The Mechanical and Thermodynamical Theory of Plasticity (Mehrdad Negahban)

- The Highly Sensitive Person Broadway - Elaine N. Aron Ph.D. (1997)

- Advanced Marine Electrics and Electronics Troubleshooting - A Manual for Boatowners and Marine Technicians (Ed Sherman)

- Corporate Finance 6th (Ross & Westerfield & Jaffe)

- Mechanics of Materials 6th (Beer Johnston)

- 100 Cases in Paediatrics (Joseph Raine)

- Automobile Electrical and Electronic Systems (Tom Denton)

- Composite Materials Design and Applications - Third Edition (Daniel Gay)

- Soil Mechanics - Concepts and Applications Second Edition (William Powrie)

- Producing Fuels and Fine Chemicals from Biomass Using Nanomaterials (Rafael Luque & Alina Mariana Balu)

- Compressed air operations manual (Brian Elliott)

- Standard Handbook of Machine Design (Joseph E. Shigley & Charles R. Mischke & Thomas H.Brown)

- Tài liệu học tiếng Pháp - Easy French STEP BY STEP (Myrna Bell Rochester)

- Microelectronic Circuit Design (Richard Jaeger)

- Computational Fluid Dynamics (T. J. Chung)

- Modern RF and Microwave Measurement Techniques (The Cambridge RF and Microwave Engineering Series) - (Valeria Teppati & Andrea)

- English Vocabulary in Use Advanced Book with Answers Vocabulary Reference and Practice - Michael McCarthy, Felicity O Dell

- Introduction to Communication Systems (Upamanyu Madhow)

- THE ART OF ELECTRONICS - Third Edition (Paul Horowitz & Winfield Hill)

- Vibration of Mechanical Systems (Alok Sinha)

- Professional English in Use Medicine (Từ điển chuyên ngành y khoa) - Eric H. Glendinning

- Electromagnetics (Electrical Engineering Textbook Series) - (Edward J. Rothwell & Michael J. Cloud)

- Renewable Energy Resources 3 edition (John Twidell)

- Electrical Wiring Industrial 15th Edition (Stephen L. Herman)

- Electricity and controls for HVACR 6th (Stephen L. Herman)

- Power Equipment Engine Technology (Edward Abdo)

- BRUCE ROGERS COMPLETE Guide to the TOEIC ® TEST (FULL)

- Heat transfer Tenth Edition (J. P. Holman)

- Mechanical Engineering 3rd edition (Alan Darbyshire)

- Stability Design of Steel Frames (W. F. Chen & E. M. Lui)

- Testing and balancing HVAC air and water systems (Samuel C. Sugarman)

- Mechatronics An Introduction (Robert H. Bishop)

- A First Course in Finite Elements (Jacob Fish & Ted Belytschko)

- Geometric and Engineering Drawing - Third Edition (K . MORLING)

- Heat Exchanger Design Handbook Second Edition (Kuppan Thulukkanam)

- Bank Management - 8th Edition (Timothy W. Koch & S. Scott MacDonald)

- Engineering Fundamentals (Roger L. Timings)

- Compressor Handbook (Paul C. Hanlon)

- Wind Loading of Structures [2nd Edition] - John D. Holmes

- The Cambridge Grammar of the English Language (Rodney Huddleston)

- Electronic Circuits - Fundamentals and applications (Mike Tooley)

- Power System SCADA and Smart Grids (Mini S. Thomas & John D. McDonald)

- Design and Optimization of Thermal Systems 2 Ed (Yogesh Jaluria)

- The Electric Generators Handbook - Synchronous Generators (Ion Boldea)

- HVAC Design Sourcebook (W. Larsen Angel)

- Manufacturing Engineering and Technology 17th Ed (Serope Kalpakjian)

- Principles of Chemical Engineering Processes - Material and Energy Balances 2th (Nayef Ghasem)

- Electric Machines and Drives (Ned Mohan)

- Light The Medicine of the Future (Jacob Liberman)

- FIRE, SMOKE AND RADIATION DAMPER INSTALLATION GUIDE FOR HVAC SYSTEMS - SMACNA

- Planning and Installing Solar Thermal Systems - A Guide for Installers Architects and Engineers (Dgs)

- Professional English in Use - Law (Gillian D. Brown, Sally Rice)

- Reinforced concrete mechanics and design - James G. MacGregor (Full Update)

- Synchronous Generators 2 Ed (Ion Boldea)

- Water treatment plant design (Fifth Edition)

- Natural Language Processing in Action

- Advanced Grammar in Use with Answers (Martin Hewings)

- Test bank solution of human resource management 15e by gary dessler 2017 chapter 01,02,03,04,05,06,07

- Moonwalking with Einstein The Art and Science of Remembering Everything - Joshua Foer

- English Collocations in Use Intermediate (Michael McCarthy & Felicity O Dell)

- Mathematics Manual for Water and Wastewater Treatment Plant Operators - 2nd Edition (Frank R. Spellman)

- APRENDE GRAMATICA Y VOCABULARIO 1 (FRANCISCA CASTRO VIUDEZ)

- Machine Tool Practices 9th Edition (Richard R. Kibbe)

- Electronic devices (Thomas L. Floyd)

- MODERN OPERATING SYSTEMS FOURTH EDITION (ANDREWS. TANENBAUM & HERBERT BOS)

- Electronics All In One For Dummies - 8 & 9 Books in one - Full (Doug Lowe)

LINK DOWNLOAD EBOOK >>> CONTACT GROUP EBOOKBKMT

LIST TECHNICAL DOCUMENTS SUPPORTED PRIVATE BY GROUP EBOOKBKMT (UPDATE CONTINUOUS ...)

Các tài liệu này do vấn đề liên quan đến bản quyền được thông báo từ các chủ sở hữu nên EBOOKBKMT sẽ không đăng tải lên thư viên.

Các bạn liên hệ qua Group hoặc Inbox Page EBOOKBKMT để nhận link tải cá nhân cho các tài liệu có tên theo list ở bên dưới.

LINK DOWNLOAD EBOOK >>> CONTACT GROUP EBOOKBKMT

- Water and Wastewater Conveyance Pumping Hydraulics Piping and Valves (Frank R. Spellman)

- How Psychology Works Applied Psychology Visually Explained (DK, Jo Hemmings)

- Beginning DirectX 9 (Wendy Jones - Vngamedev)

- Beginning DirectX 9 - Wendy Jones

- Engineering Analysis with SOLIDWORKS Simulation 2018 - Paul M Kurowski

- Mechanical Fastening Joining and Assembly 2nd Edition (James A. Speck)

- Safety Management near Miss Identification Recognition and Investigation (Ron C. McKinnon)

- Transformer Engineering Design Technology and Diagnostics 2nd Edition (S. V. Kulkarni and S. A. Khaparde)

- Aging Power Delivery Infrastructures 2 Ed (H. Lee Willis & Randall R. Schrieber)

- Compressor handbook principles and practice (Tony Giampaolo)

- Fundamentals of Geotechnical Engineering (Braja M. Das)

- Environmental degradation of advanced and traditional engineering materials (Lloyd H. Hihara)

- Handbook of Automotive Power Electronics and Motor Drives (Ali Emadi)

- The Gas Turbine Handbook - Principles and Practices (Tony Giampaolo & Anthony J. Giampaolo)

- Advanced automotive fault diagnosis (Tom Denton)

- Welding for arts & crafts (Dewayne Roy)

- Digital Design and Verilog HDL Fundamentals (Joseph Cavanagh)

- A First Course in the Finite Element Method (Daryl L. Logan)

- Power Vacuum Tubes Handbook Third Edition (Electronics Handbook Series) - Jerry Whitaker

- Analysis of Synchronous Machines Second Edition (T.A. Lipo)

- Engineering Design Process (Yousef Haik & Tamer M. Shahin)

- Essential DC/DC Converters (Fang Lin Luo)

- Vibration Problems in Machines - Diagnosis and Resolution (Arthur W. Lees)

- Ductile Design of Steel Structures (Michel Bruneau & Chia-Ming Uang & Rafael Sabelli)

- The Mechatronics Handbook - Cơ điện tử Tập 1 (Robert H. Bishop - Phạm Anh Tuấn Bd)

- The mechatronics handbook (Robert H. Bishop)

- Beginning DirectX 9 (Wendy Jones - Vngamedev Biên dịch)

- Stability Design of Steel Frames (W. F. Chen & E. M. Lui)

- Planning and Installing Solar Thermal Systems - A Guide for Installers Architects and Engineers (Dgs)

- Synchronous Generators 2 Ed (Ion Boldea)

- English for business communication - Student's book (Simon Sweeney) - PREVIEW

- Professional English in Use - Law (Gillian D. Brown, Sally Rice)

- Modern electric, hybrid electric, and fuel cell vehicles: fundamentals, theory, and design - Mehrdad Ehsani , Yimin Gao , Sebastien E. Gay , Ali Emadi

- Water Wells and Pumps (A. M. Michael & S. D. Khepar & S. K. Sondhi)

- Optical Fiber Sensors Advanced Techniques and Applications (Ginu Rajan)

- Audio Engineer's Reference Book 2nd edition (Michael Talbot - Smith)

- Thermodynamics and Heat Power Eighth Edition (Irving Granet)

- Flight Vehicle Aerodynamics (Mark Drela)

- Boilers for power and process (Kumar Rayaprolu)

- Introduction to Microsystem Packaging Technology (Yufeng Jin)

- Handbook of Research for Mechanical Engineering - Applied Research in Hydraulics and Heat Flow (Kaveh Hariri Asli)

- Materials Handbook (George Stuart Brady & Henry R. Clauser & John A. Vaccari)

- Troubleshooting and Repairing Commercial Electrical Equipment (David Herres)

- Cybersecurity for Industrial Control Systems SCADA, DCS, PLC, HMI, and SIS - Tyson Macaulay, Bryan L.Singer

- Audio Power Amplifier Design Handbook - Third edition (Douglas Self)

- Mechanical Design of Electric Motors (Wei Tong)

- Alternative Energy Technologies - An Introduction with Computer Simulations (Gavin Buxton)

- Air Conditioning - A practical introduction - Third edition (David V. Chadderton)

- Improving Concrete Quality (Karthikeyan H. Obla)

- The Principles of Thermodynamics (N. D. Hari Dass)

- Optical Imaging Devices - New Technologies and Applications (Ajit Khosla & Dongsoo Kim)

- Automotive computer controlled systems (Allan Bonnick)

- The Mechanical and Thermodynamical Theory of Plasticity (Mehrdad Negahban)

- The Highly Sensitive Person Broadway - Elaine N. Aron Ph.D. (1997)

- Advanced Marine Electrics and Electronics Troubleshooting - A Manual for Boatowners and Marine Technicians (Ed Sherman)

- Corporate Finance 6th (Ross & Westerfield & Jaffe)

- Mechanics of Materials 6th (Beer Johnston)

- 100 Cases in Paediatrics (Joseph Raine)

- Automobile Electrical and Electronic Systems (Tom Denton)

- Composite Materials Design and Applications - Third Edition (Daniel Gay)

- Soil Mechanics - Concepts and Applications Second Edition (William Powrie)

- Producing Fuels and Fine Chemicals from Biomass Using Nanomaterials (Rafael Luque & Alina Mariana Balu)

- Compressed air operations manual (Brian Elliott)

- Standard Handbook of Machine Design (Joseph E. Shigley & Charles R. Mischke & Thomas H.Brown)

- Tài liệu học tiếng Pháp - Easy French STEP BY STEP (Myrna Bell Rochester)

- Microelectronic Circuit Design (Richard Jaeger)

- Computational Fluid Dynamics (T. J. Chung)

- Modern RF and Microwave Measurement Techniques (The Cambridge RF and Microwave Engineering Series) - (Valeria Teppati & Andrea)

- English Vocabulary in Use Advanced Book with Answers Vocabulary Reference and Practice - Michael McCarthy, Felicity O Dell

- Introduction to Communication Systems (Upamanyu Madhow)

- THE ART OF ELECTRONICS - Third Edition (Paul Horowitz & Winfield Hill)

- Vibration of Mechanical Systems (Alok Sinha)

- Professional English in Use Medicine (Từ điển chuyên ngành y khoa) - Eric H. Glendinning

- Electromagnetics (Electrical Engineering Textbook Series) - (Edward J. Rothwell & Michael J. Cloud)

- Renewable Energy Resources 3 edition (John Twidell)

- Electrical Wiring Industrial 15th Edition (Stephen L. Herman)

- Electricity and controls for HVACR 6th (Stephen L. Herman)

- Power Equipment Engine Technology (Edward Abdo)

- BRUCE ROGERS COMPLETE Guide to the TOEIC ® TEST (FULL)

- Heat transfer Tenth Edition (J. P. Holman)

- Mechanical Engineering 3rd edition (Alan Darbyshire)

- Stability Design of Steel Frames (W. F. Chen & E. M. Lui)

- Testing and balancing HVAC air and water systems (Samuel C. Sugarman)

- Mechatronics An Introduction (Robert H. Bishop)

- A First Course in Finite Elements (Jacob Fish & Ted Belytschko)

- Geometric and Engineering Drawing - Third Edition (K . MORLING)

- Heat Exchanger Design Handbook Second Edition (Kuppan Thulukkanam)

- Bank Management - 8th Edition (Timothy W. Koch & S. Scott MacDonald)

- Engineering Fundamentals (Roger L. Timings)

- Compressor Handbook (Paul C. Hanlon)

- Wind Loading of Structures [2nd Edition] - John D. Holmes

- The Cambridge Grammar of the English Language (Rodney Huddleston)

- Electronic Circuits - Fundamentals and applications (Mike Tooley)

- Power System SCADA and Smart Grids (Mini S. Thomas & John D. McDonald)

- Design and Optimization of Thermal Systems 2 Ed (Yogesh Jaluria)

- The Electric Generators Handbook - Synchronous Generators (Ion Boldea)

- HVAC Design Sourcebook (W. Larsen Angel)

- Manufacturing Engineering and Technology 17th Ed (Serope Kalpakjian)

- Principles of Chemical Engineering Processes - Material and Energy Balances 2th (Nayef Ghasem)

- Electric Machines and Drives (Ned Mohan)

- Light The Medicine of the Future (Jacob Liberman)

- FIRE, SMOKE AND RADIATION DAMPER INSTALLATION GUIDE FOR HVAC SYSTEMS - SMACNA

- Planning and Installing Solar Thermal Systems - A Guide for Installers Architects and Engineers (Dgs)

- Professional English in Use - Law (Gillian D. Brown, Sally Rice)

- Reinforced concrete mechanics and design - James G. MacGregor (Full Update)

- Synchronous Generators 2 Ed (Ion Boldea)

- Water treatment plant design (Fifth Edition)

- Natural Language Processing in Action

- Advanced Grammar in Use with Answers (Martin Hewings)

- Test bank solution of human resource management 15e by gary dessler 2017 chapter 01,02,03,04,05,06,07

- Moonwalking with Einstein The Art and Science of Remembering Everything - Joshua Foer

- English Collocations in Use Intermediate (Michael McCarthy & Felicity O Dell)

- Mathematics Manual for Water and Wastewater Treatment Plant Operators - 2nd Edition (Frank R. Spellman)

- APRENDE GRAMATICA Y VOCABULARIO 1 (FRANCISCA CASTRO VIUDEZ)

- Machine Tool Practices 9th Edition (Richard R. Kibbe)

- Electronic devices (Thomas L. Floyd)

- MODERN OPERATING SYSTEMS FOURTH EDITION (ANDREWS. TANENBAUM & HERBERT BOS)

- Electronics All In One For Dummies - 8 & 9 Books in one - Full (Doug Lowe)

LINK DOWNLOAD EBOOK >>> CONTACT GROUP EBOOKBKMT

%20(1).png)

.png)

%20(1)%20(1).png.png)

.png)

%20(1).png)

%20(1).png)

Không có nhận xét nào: