EBOOK - Repair of Vehicle Bodies - Fifth Edition (W.A.Livesey & A. Robinson)

EBOOK - Repair of Vehicle Bodies - (W.A.Livesey & A. Robinson) - 676 Trang.

This book is written for a wide range of students and professional ractitioners in the field of vehicle body repair and re-finishing. It is a text book and reference work which covers the concepts, principles and skills needed to carry out effective vehicle body repair and re-finishing.

It will be useful for the professional practitioner whether working on current models or restoring vintage or classic cars. The DIY enthusiast will find it easy to read and useful as a work-shop manual when carrying out tasks, or projects, related to the vehicle body.

Students who are studying for NVQ, SNVQ, National Diploma, Higher National Diploma or Foundation Degree qualifications in motor vehicle engineering will find the book an ideal text and reference book for both the practical skills and the examinable content of those courses.

For NVQ/SNVQ students, Tables P1 and P2 will help in portfolio planning. Table P1 shows the qualification framework for Vehicle and Body Paint Operations Units from Automotive Skills Limited.

Table P2 links the qualification framework with the contents of the book, showing which sections in the book relate to specific units. This table will help guide readers who are using the book as a course text or reference, with links to the underpinning knowledge and skills as well as to the material included in the NVQ assessment.

1 The history, development and construction of the car body 1

1.1 Development of the motor car body 1

1.2 Creation of a new design from concept to realization 14

1.3 Methods of construction 32

1.4 Basic body construction 37

1.5 Identification of major body pressings 43

1.6 Vehicle type approval 52

Questions 57

2 Health and safety 59

2.1 Personal safety and health practices 59

2.2 Fire precautions 65

2.3 Safety signs in the workshop 70

2.4 General safety precautions in the workshop 72

2.5 Electrical hazards 75

2.6 COSHH 75

2.7 RIDDOR 75

2.8 Maintain the health, safety and security of the work environment 76

Questions 84

3 Hand and power tools 85

3.1 Hand tools used in body repair work 85

3.2 Hammers 85

3.3 Hand Dollies 88

3.4 Body spoons 89

3.5 Body files 90

3.6 Hand snips 91

3.7 Specialist panel beating tools 92

3.8 Recommended basic toolkits for panel beaters 97

3.9 Hand tools used in the fabrication of sheet metal 98

3.10 Hammers and mallets 98

3.11 Sandbags and hardwood blocks 100

viii Contents

3.12 Sheet metal bench stakes 100

3.13 Hand grooving tools 102

3.14 Rivet sets 102

3.15 Cutting tools 102

3.16 Bending and swaging tools 104

3.17 General-purpose assembly and dismantling tools 105

3.18 Power tools used in body repair work 109

3.19 Air power chisel 110

3.20 Metal cutting shears and nibblers 110

3.21 Power saw 113

3.22 Power drills 113

3.23 Sanding machines 114

3.24 Other power tools 117

3.25 Dust extraction for power tools 119

Questions 121

4 Metals and non-metals used in vehicle bodies 122

4.1 Manufacture of steel coil and sheet for the automobile industry 122

4.2 Specifications of steels used in the automobile industry 123

4.3 Carbon steel 124

4.4 Alloy steels 130

4.5 Stainless steel 132

4.6 Aluminium 133

4.7 Aluminium alloys 134

4.8 Rubber 141

4.9 Sealers 142

4.10 Sound deadening, thermal insulating and undersealing materials 144

4.11 Interior furnishings 146

4.12 Plastics 148

4.13 Plastics repair 153

4.14 Safety glass 156

Questions 158

5 Metal forming processes and machines 160

5.1 Properties of metals 160

5.2 Heat treatment of metals and metal alloys 163

5.3 How metal is formed to provide strength 167

5.4 Machines for sheet metal fabrication 169

5.5 Shearing theory 169

5.6 Cutting machines 169

5.7 Bending theory 171

5.8 Bending machines 172

5.9 Rolling machines 173

5.10 Wheeling machines 175

5.11 Swaging machines 176

5.12 Brake presses 178

5.13 Forming and drawing 180

5.14 Sheet metal cutting for press work 182

Questions 182

6 Measuring and marking-out instruments 184

6.1 Marking out 184

6.2 Basic marking-out and measuring instruments 185

6.3 Precision marking-out and measuring instruments 192

Questions 196

7 Methods of joining 197

7.1 Development of joining methods 197

7.2 Solid rivets 197

7.3 Bifurcated, tubular and semitubular rivets 199

7.4 Blind rivets 200

7.5 Structural fasteners 208

7.6 Screws and bolts 211

7.7 Fastening devices 218

7.8 Adhesives 223

Questions 233

8 Soft and hard soldering methods 235

8.1 Comparison of fusion and non-fusion jointing processes 235

8.2 Soft and hard solders 236

8.3 Soft soldering 236

8.4 Hard soldering 240

Questions 247

9 Gas welding, gas cutting and plasma arc cutting 248

9.1 Development of gas welding 248

9.2 Systems of gas welding 249

9.3 Oxy-acetylene welding equipment 250

9.4 Definitions of welding terms 256

9.5 Welding rods and fluxes 257

9.6 Flame control and types of flame 257

9.7 Methods of welding 259

9.8 Edge preparation and types of joint 260

9.9 Welding technique: butt joint in mild steel 263

9.10 Welding various metals 263

9.11 Gas cutting 264

9.12 Gases: characteristics and colour coding 266

9.13 Safety measures 268

9.14 Plasma arc cutting 271

Questions 275

10 Electric resistance welding 277

10.1 Resistance welding in car body manufacture 277

10.2 Resistance spot welding 279

10.3 Resistance projection welding 280

10.4 Resistance seam welding 280

10.5 Resistance flash welding 281

10.6 Resistance butt welding 281

10.7 Resistance welding in body repair work 282

...

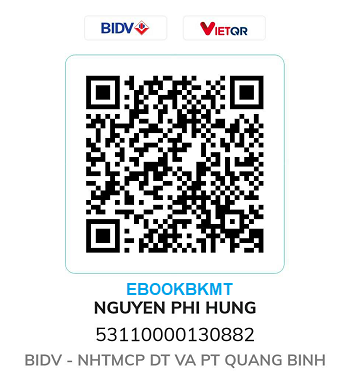

LINK DOWNLOAD

EBOOK - Repair of Vehicle Bodies - (W.A.Livesey & A. Robinson) - 676 Trang.

This book is written for a wide range of students and professional ractitioners in the field of vehicle body repair and re-finishing. It is a text book and reference work which covers the concepts, principles and skills needed to carry out effective vehicle body repair and re-finishing.

It will be useful for the professional practitioner whether working on current models or restoring vintage or classic cars. The DIY enthusiast will find it easy to read and useful as a work-shop manual when carrying out tasks, or projects, related to the vehicle body.

Students who are studying for NVQ, SNVQ, National Diploma, Higher National Diploma or Foundation Degree qualifications in motor vehicle engineering will find the book an ideal text and reference book for both the practical skills and the examinable content of those courses.

For NVQ/SNVQ students, Tables P1 and P2 will help in portfolio planning. Table P1 shows the qualification framework for Vehicle and Body Paint Operations Units from Automotive Skills Limited.

Table P2 links the qualification framework with the contents of the book, showing which sections in the book relate to specific units. This table will help guide readers who are using the book as a course text or reference, with links to the underpinning knowledge and skills as well as to the material included in the NVQ assessment.

1 The history, development and construction of the car body 1

1.1 Development of the motor car body 1

1.2 Creation of a new design from concept to realization 14

1.3 Methods of construction 32

1.4 Basic body construction 37

1.5 Identification of major body pressings 43

1.6 Vehicle type approval 52

Questions 57

2 Health and safety 59

2.1 Personal safety and health practices 59

2.2 Fire precautions 65

2.3 Safety signs in the workshop 70

2.4 General safety precautions in the workshop 72

2.5 Electrical hazards 75

2.6 COSHH 75

2.7 RIDDOR 75

2.8 Maintain the health, safety and security of the work environment 76

Questions 84

3 Hand and power tools 85

3.1 Hand tools used in body repair work 85

3.2 Hammers 85

3.3 Hand Dollies 88

3.4 Body spoons 89

3.5 Body files 90

3.6 Hand snips 91

3.7 Specialist panel beating tools 92

3.8 Recommended basic toolkits for panel beaters 97

3.9 Hand tools used in the fabrication of sheet metal 98

3.10 Hammers and mallets 98

3.11 Sandbags and hardwood blocks 100

viii Contents

3.12 Sheet metal bench stakes 100

3.13 Hand grooving tools 102

3.14 Rivet sets 102

3.15 Cutting tools 102

3.16 Bending and swaging tools 104

3.17 General-purpose assembly and dismantling tools 105

3.18 Power tools used in body repair work 109

3.19 Air power chisel 110

3.20 Metal cutting shears and nibblers 110

3.21 Power saw 113

3.22 Power drills 113

3.23 Sanding machines 114

3.24 Other power tools 117

3.25 Dust extraction for power tools 119

Questions 121

4 Metals and non-metals used in vehicle bodies 122

4.1 Manufacture of steel coil and sheet for the automobile industry 122

4.2 Specifications of steels used in the automobile industry 123

4.3 Carbon steel 124

4.4 Alloy steels 130

4.5 Stainless steel 132

4.6 Aluminium 133

4.7 Aluminium alloys 134

4.8 Rubber 141

4.9 Sealers 142

4.10 Sound deadening, thermal insulating and undersealing materials 144

4.11 Interior furnishings 146

4.12 Plastics 148

4.13 Plastics repair 153

4.14 Safety glass 156

Questions 158

5 Metal forming processes and machines 160

5.1 Properties of metals 160

5.2 Heat treatment of metals and metal alloys 163

5.3 How metal is formed to provide strength 167

5.4 Machines for sheet metal fabrication 169

5.5 Shearing theory 169

5.6 Cutting machines 169

5.7 Bending theory 171

5.8 Bending machines 172

5.9 Rolling machines 173

5.10 Wheeling machines 175

5.11 Swaging machines 176

5.12 Brake presses 178

5.13 Forming and drawing 180

5.14 Sheet metal cutting for press work 182

Questions 182

6 Measuring and marking-out instruments 184

6.1 Marking out 184

6.2 Basic marking-out and measuring instruments 185

6.3 Precision marking-out and measuring instruments 192

Questions 196

7 Methods of joining 197

7.1 Development of joining methods 197

7.2 Solid rivets 197

7.3 Bifurcated, tubular and semitubular rivets 199

7.4 Blind rivets 200

7.5 Structural fasteners 208

7.6 Screws and bolts 211

7.7 Fastening devices 218

7.8 Adhesives 223

Questions 233

8 Soft and hard soldering methods 235

8.1 Comparison of fusion and non-fusion jointing processes 235

8.2 Soft and hard solders 236

8.3 Soft soldering 236

8.4 Hard soldering 240

Questions 247

9 Gas welding, gas cutting and plasma arc cutting 248

9.1 Development of gas welding 248

9.2 Systems of gas welding 249

9.3 Oxy-acetylene welding equipment 250

9.4 Definitions of welding terms 256

9.5 Welding rods and fluxes 257

9.6 Flame control and types of flame 257

9.7 Methods of welding 259

9.8 Edge preparation and types of joint 260

9.9 Welding technique: butt joint in mild steel 263

9.10 Welding various metals 263

9.11 Gas cutting 264

9.12 Gases: characteristics and colour coding 266

9.13 Safety measures 268

9.14 Plasma arc cutting 271

Questions 275

10 Electric resistance welding 277

10.1 Resistance welding in car body manufacture 277

10.2 Resistance spot welding 279

10.3 Resistance projection welding 280

10.4 Resistance seam welding 280

10.5 Resistance flash welding 281

10.6 Resistance butt welding 281

10.7 Resistance welding in body repair work 282

...

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

Không có nhận xét nào: