EBOOK - Compressed Air Engineering (Kaeser)

EBOOK - Kỹ thuật khí nén - Tác giả: Kaeser.

It’s the same with compressed air as with many other things in life: a small cause can have a large effect – both in a positive and negative sense. Upon closer inspection things are often different from how they at first appear. In unfavourable conditions compressed air can be expensive, but in the right circumstances it is very economical. In this first chapter we will explain the terms used in compressed air engineering and the things you should watch for in connection with them.

1. Free air delivery.

The air delivery of a compressor (known also as the free air delivery or FAD) is the expanded volume of air it forces into the air main (network) over a given period of time. The correct method of measuring this volume is given in the following standards: DIN 1945, Part 1, Annex Fand ISO 1217, Annex C. The measurement process is performed as follows as shown in Fig. 1: the temperature, atmospheric pressure and humidity must first be measured at the air inlet of the compressor package.

Then, the maximum working pressure, temperature and volume of compressed air discharged from the compressor are measured. Finally, the volume V2 measured at the compressor outlet is referred back to the inlet conditions using the shown equation (see formula).

Fundamentals of compressed air production.

Efficient compressed air treatment.

Why do we need to dry compressed air ?.

Condensate: Correct drainage.

Condensate: Safe, economical treatment.

Efficient compressor control

Optimised compressor performance to meet actual demand.

Energy savings with heat recovery.

Designing and installing a new compressed air distribution network.

Optimising an existing air distribution network.

Compressed air demand analysis (ADA) – Determining the current situation.

Determining the most efficient concept.

Efficient compressor station cooling.

Ensuring long-term reliability and cost-optimisation.

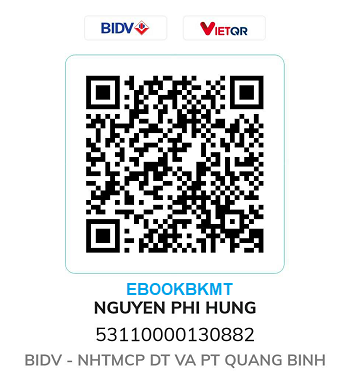

LINK DOWNLOAD

EBOOK - Kỹ thuật khí nén - Tác giả: Kaeser.

It’s the same with compressed air as with many other things in life: a small cause can have a large effect – both in a positive and negative sense. Upon closer inspection things are often different from how they at first appear. In unfavourable conditions compressed air can be expensive, but in the right circumstances it is very economical. In this first chapter we will explain the terms used in compressed air engineering and the things you should watch for in connection with them.

1. Free air delivery.

The air delivery of a compressor (known also as the free air delivery or FAD) is the expanded volume of air it forces into the air main (network) over a given period of time. The correct method of measuring this volume is given in the following standards: DIN 1945, Part 1, Annex Fand ISO 1217, Annex C. The measurement process is performed as follows as shown in Fig. 1: the temperature, atmospheric pressure and humidity must first be measured at the air inlet of the compressor package.

Then, the maximum working pressure, temperature and volume of compressed air discharged from the compressor are measured. Finally, the volume V2 measured at the compressor outlet is referred back to the inlet conditions using the shown equation (see formula).

Fundamentals of compressed air production.

Efficient compressed air treatment.

Why do we need to dry compressed air ?.

Condensate: Correct drainage.

Condensate: Safe, economical treatment.

Efficient compressor control

Optimised compressor performance to meet actual demand.

Energy savings with heat recovery.

Designing and installing a new compressed air distribution network.

Optimising an existing air distribution network.

Compressed air demand analysis (ADA) – Determining the current situation.

Determining the most efficient concept.

Efficient compressor station cooling.

Ensuring long-term reliability and cost-optimisation.

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

Không có nhận xét nào: