EBOOK - Handbook Of Natural Gas Transmission and Processing (Saeid Mokhatab)

EBOOK - Sổ tay công nghệ truyền tải khí đốt (Saeid Mokhatab) - 666 Trang.

Natural gas is an emergent fuel of choice for environmentally aware due to the lower noxious emissions compared with other fossil fuels. Exploration activity by major multinational oil and gas companies is aimed increasingly to find gas in remote locations and in ever deeper ocean depths. Once a gas field has been discovered, the gas accumulation must be developed, produced, gathered, processed, and transported to the consumer. Transport of gas by pipelines to distant delivery points presents unique challenges of flow through long conduits.

Processing of the gas to meet delivery specifications is required and this requires process systems design for each production facility. With this book we have sought to provide a comprehensive technical text that reflects a broad spectrum of natural gas transmission and processing experience. This handbook has been written to assist both the novice and the experienced technical professional in natural gas engineering practice. Emphasis is placed on developing the fundamental concepts and tools of the subject and on discussing basic applications for engineering purposes.

To keep things interesting for the expert, we have sought to include the most current developments reported in the latest published works in the research journals. The selection of some of the material also reflects our own research involvement in problems related to natural gas engineering. We have also taken advantage of some authoritative publications and papers published in the recent years from different sources as well as standards and recommendations published by several research institutions. Therefore, readers are strongly recommended to study the references indicated in the text to find more details on each subject.

CONTENTS:

1 Natural Gas Fundamental 1

1.1 Introduction 1

1.2 Natural Gas History 2

1.3 Natural Gas Origin and Composition 2

1.4 Gas Sources 4

1.4.1 Non-associated Gas 4

1.4.2 Associated Gas 5

1.4.3 Coal Bed Methane 6

1.5 Natural Gas Phase Behavior 8

1.6 Natural Gas Properties 9

1.6.1 Chemical and Physical Properties 9

1.6.2 Gas-Specific Gravity 10

1.6.3 Ideal and Real Gas Laws 11

1.6.4 Gas Formation Volume Factor 15

1.6.5 Gas Density 16

1.6.6 Isothermal Compressibility of Gases 17

1.6.7 Gas Viscosity 17

1.7 Quality 18

1.8 Transportation 19

1.8.1 Pipelines 19

1.8.2 Liquefied Natural Gas 19

1.8.3 Compressed Natural Gas 20

1.8.4 Gas to Solid 22

1.8.5 Gas to Power 24

1.8.6 Gas to Liquids 25

1.8.7 Gas to Commodity 26

References 27

2 Natural Gas Energy Pricing 29

2.1 Introduction 29

2.2 Energy Pricing, Supply, and Demand 30

2.3 Sustainability and the Increasing Fascination with

Natural Gas 32

2.4 Is Natural Gas Always “Nonrenewable?” 34

2.5 U.S. Natural Gas: Pricing, Markets, Risk Management,

and Supply 37

2.5.1 Some Features of Current Natural Gas Pricing in the

United States 37

2.5.2 U.S. Energy Markets: The Regulation–Deregulation

Nexus 41

2.5.3 Energy Price Volatility and Derivatives 43

2.5.4 Natural Gas Supply in North America 48

2.6 Natural Gas in Eurasia: The Special Position of

Post-Soviet Russia 63

2.7 Looking to Nature for a New Model 69

References 78

3 Raw Gas Transmission 81

3.1 Introduction 81

3.2 Multiphase Flow Terminology 82

3.2.1 Superficial Velocity 83

3.2.2 Multiphase Flow Mixture Velocity 84

3.2.3 Holdup 84

3.2.4 Phase Velocity 85

3.2.5 Slip 85

3.2.6 Multiphase Flow Density 85

3.3 Multiphase Flow Regimes 86

3.3.1 Two-Phase Flow Regimes 87

3.3.2 Three-Phase Flow Regimes 94

3.4 Calculating Multiphase Flow Pressure Gradients 95

3.4.1 Steady-State Two-Phase Flow 95

3.4.2 Steady-State Three-Phase Flow 103

3.4.3 Transient Multiphase Flow 104

3.5 Multiphase Flow in Gas/Condensate Pipelines 107

3.6 Temperature Profile of Multiphase Pipelines 109

3.7 Velocity Criteria for Sizing Multiphase Pipelines 112

3.7.1 Erosion Criteria 112

3.7.2 Corrosion Criteria 116

3.8 Multiphase Flow Assurance 117

3.8.1 Gas Hydrates 117

3.8.2 Corrosion 136

3.8.3 Wax 140

3.8.4 Severe Slugging 153

3.8.5 Real-Time Flow Assurance Monitoring 163

3.9 Multiphase Pipeline Operations 163

3.9.1 Leak Detection 163

3.9.2 Pigging 165

References 173

4 Basic Concepts of Natural Gas Processing 189

4.1 Introduction 189

4.2 Process Modules 190

4.3 Scope of Natural Gas Processing 193

4.3.1 Processing Objectives 193

4.3.2 Effect of Gas Type in Field Processing 194

4.3.3 Location of the Gas Field 195

References 195

5 Phase Separation 197

5.1 Introduction 197

5.2 Gravity Separators 198

5.2.1 General Description 199

5.2.2 Separator Selection 201

5.2.3 Gravity Separation Theory 203

5.2.4 Design Considerations 206

5.2.5 Design Procedure 206

5.2.6 Practical Separator Design 216

5.2.7 Operating Problems 217

5.3 Multistage Separation 219

5.4 Centrifugal Separators 220

5.5 Twister Supersonic Separator 221

5.6 Slug Catchers 221

5.7 High-Efficiency Liquid–Gas Coalescers 224

5.7.1 Aerosols 224

5.7.2 Coalescer Construction/Operation Principles 225

5.7.3 Modeling the Liquid/Gas Coalescer 228

5.7.4 Coalescer Performance/Operational Limits 231

5.7.5 Liquid/Gas Coalescer Applications 233

5.8 High-Efficiency Liquid–Liquid Coalescers 236

5.8.1 Emulsions 236

5.8.2 Coalescer Principles and Materials of Construction 237

5.8.3 Coalescer Mechanism of Operation 238

5.8.4 Liquid/Liquid Coalescer Performance 241

5.8.5 Limitations of Using Coalescers 242

5.8.6 Applications 242

References 244

6 Condensate Stabilization 247

6.1 Introduction 247

6.2 Stabilization Processes 248

6.2.1 Flash Vaporization 248

6.2.2 Stabilization by Fractionation 249

6.3 Condensate Storage 256

References 259

7 Acid Gas Treating 261

7.1 Introduction 261

7.2 Acid Gas Removal Processes 262

7.2.1 Batch Type Processes 264

7.2.2 Amine Processes 270

7.2.3 Carbonate Washing and Water Washing 281

7.2.4 Methanol Based Processes 282

7.2.5 Other Processes 284

7.2.6 Process Selection 287

7.3 Sulfur Recovery Processes 288

References 291

8 Natural Gas Compression 295

8.1 Introduction 295

8.2 Reciprocating Compressors 296

8.3 Centrifugal Compressors 298

8.4 Comparison between Compressors 299

8.5 Compressor Selection 300

8.6 Thermodynamics of Gas Compression 301

8.7 Real Gas Behavior and Equations of State 307

8.8 Compression Ratio 309

8.9 Compression Design 311

Contents xiii

8.9.1 Determining Number of Stages 311

8.9.2 Inlet Flow Rate 312

8.9.3 Compression Power Calculation 313

8.10 Compressor Control 316

8.10.1 Reciprocating Compressors 317

8.10.2 Centrifugal Compressors 317

8.11 Compressor Performance Maps 319

8.11.1 Reciprocating Compressors 319

8.11.2 Centrifugal Compressors 320

References 321

9 Natural Gas Dehydration 323

9.1 Introduction 323

9.2 Water Content Determination 324

9.3 Glycol Dehydration 325

9.3.1 Process Description 328

9.3.2 Design Considerations 330

9.3.3 Operational Problems 341

9.4 Solid Desiccant Dehydration 346

9.4.1 Desiccant Capacity 347

9.4.2 Desiccant Selection 347

9.4.3 Process Description 350

9.4.4 Design Considerations 353

9.4.5 Operational Problems 358

References 361

10 Natural Gas Liquids Recovery 365

10.1 Introduction 365

10.2 NGL Recovery Processes 366

10.2.1 Refrigeration Processes 366

10.2.2 Lean Oil Absorption 376

10.2.3 Solid Bed Adsorption 377

10.2.4 Membrane Separation Process 379

10.2.5 Selection of NGL Recovery Processes 380

10.3 NGL Fractionation 381

10.3.1 Fractionator Operation 383

10.3.2 Types of Fractionators 385

10.3.3 Fractionator Design 386

10.3.4 Design Procedure 395

10.4 Gasoline and LPG Treating 396

10.4.1 Doctor Sweetening Process 397

xiv Contents

10.4.2 Merox Process 397

References 398

11 Sales Gas Transmission 401

11.1 Introduction 401

11.2 Gas Flow Fundamentals 401

11.2.1 General Flow Equation 402

11.2.2 Friction Factor Correlations 403

11.2.3 Practical Flow Equations 407

11.3 Predicting Gas Temperature Profile 409

11.4 Transient Flow in Gas Transmission Pipelines 414

11.5 Compressor Stations and Associated Pipeline

Installations 415

11.5.1 Compressor Drivers 416

11.5.2 Compressors Configurations 417

11.5.3 Reduction and Metering Stations 417

11.6 Design Considerations of Sales Gas Pipelines 418

11.6.1 Line Sizing Criteria 418

11.6.2 Compressor Station Spacing 421

11.6.3 Compression Power 425

11.7 Pipeline Operations 425

References 428

12 Gas Processing Plant Controls and Automation 431

12.1 Introduction 431

12.2 Early Methods of Gas Plant Automation 432

12.3 Microprocessor-Based Automation 433

12.3.1 Programmable Logic Controllers (PLC) 433

12.3.2 Distributed Control Systems (DCS) 433

12.3.3 Standards and Protocols 435

12.4 Control of Equipment and Process Systems 436

12.4.1 Gas Gathering 436

12.4.2 Gas Treating 437

12.4.3 Sulfur Recovery 438

12.4.4 Gas Dehydration 438

12.4.5 Liquids Recovery 440

12.4.6 NGL Fractionation 442

12.4.7 Centrifugal Compressors 443

12.4.8 Centrifugal Pumps 444

12.4.9 Reciprocating Pumps 444

12.4.10 Utilities 444

12.5 Automation Applications 445

12.5.1 Data Historians 445

12.5.2 Asset and Performance Management 446

12.5.3 Statistical Process Control 447

12.5.4 Advanced Regulatory Control 448

12.5.5 Multivariable Predictive Control 448

12.5.6 Optimization 450

12.5.7 Leveraging Automation 452

12.6 Condensate Stabilizer Case Study 455

References 458

Suggested Reading 459

13 Dynamic Simulation of Gas Processing Plants 461

13.1 Introduction 461

13.2 Areas of Application of Dynamic Simulation 462

13.2.1 Plant Design 462

13.2.2 Plant Operation 465

13.3 Modeling Considerations 468

13.3.1 Level of Detail in the Model 468

13.3.2 Model Speed 469

13.3.3 Equipment-Specific Considerations 470

13.4 Control of Equipment and Process Systems 472

13.4.1 Gas Gathering and Transportation 473

13.4.2 Gas Treating 473

13.4.3 Sulfur Recovery 473

13.4.4 Gas Dehydration 473

13.4.5 Liquids Recovery, Natural Gas Liquefaction 474

13.4.6 NGL Fractionation 474

13.5 Case Study I: Analysis of a Fuel Gas System Start-up 474

13.5.1 Introduction 475

13.5.2 Steady-State Analysis 476

13.5.3 Dynamic Analysis 476

13.5.4 Conclusion 477

13.6 Case Study II: Online Dynamic Model of a Trunk Pipeline 478

References 482

Suggested Reading 483

14 Environmental Aspects of Gas Processing and Use 485

14.1 Introduction 485

14.2 Environmental Impacts of Natural Gas Processing 486

14.2.1 Air Pollutant Emissions 486

14.2.2 Gas Flaring Emissions 490

14.2.3 Methane Emissions 492

14.2.4 Water Pollution 496

14.2.5 Soil Pollution 497

14.2.6 Pollution Prevention 497

14.3 Emissions from Natural Gas Use 498

14.3.1 Combustion Emissions 498

14.3.2 Acid Rain Formation 500

14.3.3 Smog Formation 500

14.3.4 Greenhouse Gas Emissions 501

14.3.5 Industrial and Electric Generation Emissions 502

14.4 Protocols and Environmental Programs 503

14.5 Environmental Management System 504

References 505

15 Maximizing Profitability of Gas Plant Assets 507

15.1 Introduction 507

15.2 The Performance Strategy: Integrated Gas Plant 509

15.3 Strategies for Organizational Behavior and Information 510

15.4 Organizational Behavior Model 510

15.4.1 Information Quality 511

15.4.2 Perception of Information 513

15.4.3 Capability to Perform 515

15.4.4 Organizational Hierarchy of Needs 518

15.4.5 Behavior 520

15.5 The Successful Information Strategy 520

15.6 The Impact of Living with Information Technology 521

15.7 Vision of the Modern Plant Operation 523

15.8 Operations Strategy 524

15.9 Model Based Asset Management 525

15.10 Optimization 526

15.10.1 Tools for Optimization 527

15.10.2 Optimization Alternatives 527

15.11 Industrial Relevance 530

15.12 The Technology Integration Challenge 531

15.13 Scientific Approach 532

15.14 Other Miscellaneous Initiatives 533

15.15 Conclusion 534

References 536

Suggested Reading 537

16 Gas Plant Project Management 539

16.1 Introduction 539

16.2 Project Management Overview 540

16.3 Industry Perspective 540

16.4 The Project Management Process 541

16.4.1 Defining Business and Project Objectives 543

16.4.2 Contracting Strategy 545

16.4.3 Conceptual Estimates and Schedules 546

16.4.4 Project Execution Planning 549

16.4.5 Pre Project Planning Measurement 550

16.4.6 The Responsibility Matrix 550

16.5 Project Controls 551

16.5.1 Project Time Line 551

16.5.2 Risk Management 552

16.6 Quality Assurance 562

16.7 Commissioning and Start-up 564

16.8 Operate and Evaluate 565

16.9 Project Closeout 565

16.10 Conclusion 566

References 567

Suggested Reading 567

Appendix 1 Three-Phase Flash Calculation for Hydrocarbon

Systems Containing Water 569

Appendix 2 Conversion Factors 577

Appendix 3 Physical Properties of Fluids 579

Glossary and Acronyms 593

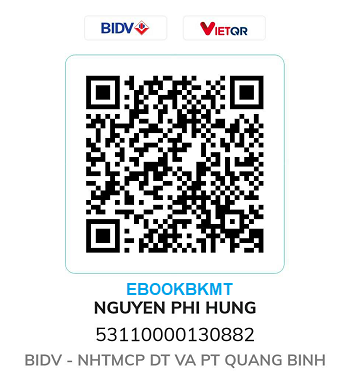

LINK DOWNLOAD

EBOOK - Sổ tay công nghệ truyền tải khí đốt (Saeid Mokhatab) - 666 Trang.

Natural gas is an emergent fuel of choice for environmentally aware due to the lower noxious emissions compared with other fossil fuels. Exploration activity by major multinational oil and gas companies is aimed increasingly to find gas in remote locations and in ever deeper ocean depths. Once a gas field has been discovered, the gas accumulation must be developed, produced, gathered, processed, and transported to the consumer. Transport of gas by pipelines to distant delivery points presents unique challenges of flow through long conduits.

Processing of the gas to meet delivery specifications is required and this requires process systems design for each production facility. With this book we have sought to provide a comprehensive technical text that reflects a broad spectrum of natural gas transmission and processing experience. This handbook has been written to assist both the novice and the experienced technical professional in natural gas engineering practice. Emphasis is placed on developing the fundamental concepts and tools of the subject and on discussing basic applications for engineering purposes.

To keep things interesting for the expert, we have sought to include the most current developments reported in the latest published works in the research journals. The selection of some of the material also reflects our own research involvement in problems related to natural gas engineering. We have also taken advantage of some authoritative publications and papers published in the recent years from different sources as well as standards and recommendations published by several research institutions. Therefore, readers are strongly recommended to study the references indicated in the text to find more details on each subject.

CONTENTS:

1 Natural Gas Fundamental 1

1.1 Introduction 1

1.2 Natural Gas History 2

1.3 Natural Gas Origin and Composition 2

1.4 Gas Sources 4

1.4.1 Non-associated Gas 4

1.4.2 Associated Gas 5

1.4.3 Coal Bed Methane 6

1.5 Natural Gas Phase Behavior 8

1.6 Natural Gas Properties 9

1.6.1 Chemical and Physical Properties 9

1.6.2 Gas-Specific Gravity 10

1.6.3 Ideal and Real Gas Laws 11

1.6.4 Gas Formation Volume Factor 15

1.6.5 Gas Density 16

1.6.6 Isothermal Compressibility of Gases 17

1.6.7 Gas Viscosity 17

1.7 Quality 18

1.8 Transportation 19

1.8.1 Pipelines 19

1.8.2 Liquefied Natural Gas 19

1.8.3 Compressed Natural Gas 20

1.8.4 Gas to Solid 22

1.8.5 Gas to Power 24

1.8.6 Gas to Liquids 25

1.8.7 Gas to Commodity 26

References 27

2 Natural Gas Energy Pricing 29

2.1 Introduction 29

2.2 Energy Pricing, Supply, and Demand 30

2.3 Sustainability and the Increasing Fascination with

Natural Gas 32

2.4 Is Natural Gas Always “Nonrenewable?” 34

2.5 U.S. Natural Gas: Pricing, Markets, Risk Management,

and Supply 37

2.5.1 Some Features of Current Natural Gas Pricing in the

United States 37

2.5.2 U.S. Energy Markets: The Regulation–Deregulation

Nexus 41

2.5.3 Energy Price Volatility and Derivatives 43

2.5.4 Natural Gas Supply in North America 48

2.6 Natural Gas in Eurasia: The Special Position of

Post-Soviet Russia 63

2.7 Looking to Nature for a New Model 69

References 78

3 Raw Gas Transmission 81

3.1 Introduction 81

3.2 Multiphase Flow Terminology 82

3.2.1 Superficial Velocity 83

3.2.2 Multiphase Flow Mixture Velocity 84

3.2.3 Holdup 84

3.2.4 Phase Velocity 85

3.2.5 Slip 85

3.2.6 Multiphase Flow Density 85

3.3 Multiphase Flow Regimes 86

3.3.1 Two-Phase Flow Regimes 87

3.3.2 Three-Phase Flow Regimes 94

3.4 Calculating Multiphase Flow Pressure Gradients 95

3.4.1 Steady-State Two-Phase Flow 95

3.4.2 Steady-State Three-Phase Flow 103

3.4.3 Transient Multiphase Flow 104

3.5 Multiphase Flow in Gas/Condensate Pipelines 107

3.6 Temperature Profile of Multiphase Pipelines 109

3.7 Velocity Criteria for Sizing Multiphase Pipelines 112

3.7.1 Erosion Criteria 112

3.7.2 Corrosion Criteria 116

3.8 Multiphase Flow Assurance 117

3.8.1 Gas Hydrates 117

3.8.2 Corrosion 136

3.8.3 Wax 140

3.8.4 Severe Slugging 153

3.8.5 Real-Time Flow Assurance Monitoring 163

3.9 Multiphase Pipeline Operations 163

3.9.1 Leak Detection 163

3.9.2 Pigging 165

References 173

4 Basic Concepts of Natural Gas Processing 189

4.1 Introduction 189

4.2 Process Modules 190

4.3 Scope of Natural Gas Processing 193

4.3.1 Processing Objectives 193

4.3.2 Effect of Gas Type in Field Processing 194

4.3.3 Location of the Gas Field 195

References 195

5 Phase Separation 197

5.1 Introduction 197

5.2 Gravity Separators 198

5.2.1 General Description 199

5.2.2 Separator Selection 201

5.2.3 Gravity Separation Theory 203

5.2.4 Design Considerations 206

5.2.5 Design Procedure 206

5.2.6 Practical Separator Design 216

5.2.7 Operating Problems 217

5.3 Multistage Separation 219

5.4 Centrifugal Separators 220

5.5 Twister Supersonic Separator 221

5.6 Slug Catchers 221

5.7 High-Efficiency Liquid–Gas Coalescers 224

5.7.1 Aerosols 224

5.7.2 Coalescer Construction/Operation Principles 225

5.7.3 Modeling the Liquid/Gas Coalescer 228

5.7.4 Coalescer Performance/Operational Limits 231

5.7.5 Liquid/Gas Coalescer Applications 233

5.8 High-Efficiency Liquid–Liquid Coalescers 236

5.8.1 Emulsions 236

5.8.2 Coalescer Principles and Materials of Construction 237

5.8.3 Coalescer Mechanism of Operation 238

5.8.4 Liquid/Liquid Coalescer Performance 241

5.8.5 Limitations of Using Coalescers 242

5.8.6 Applications 242

References 244

6 Condensate Stabilization 247

6.1 Introduction 247

6.2 Stabilization Processes 248

6.2.1 Flash Vaporization 248

6.2.2 Stabilization by Fractionation 249

6.3 Condensate Storage 256

References 259

7 Acid Gas Treating 261

7.1 Introduction 261

7.2 Acid Gas Removal Processes 262

7.2.1 Batch Type Processes 264

7.2.2 Amine Processes 270

7.2.3 Carbonate Washing and Water Washing 281

7.2.4 Methanol Based Processes 282

7.2.5 Other Processes 284

7.2.6 Process Selection 287

7.3 Sulfur Recovery Processes 288

References 291

8 Natural Gas Compression 295

8.1 Introduction 295

8.2 Reciprocating Compressors 296

8.3 Centrifugal Compressors 298

8.4 Comparison between Compressors 299

8.5 Compressor Selection 300

8.6 Thermodynamics of Gas Compression 301

8.7 Real Gas Behavior and Equations of State 307

8.8 Compression Ratio 309

8.9 Compression Design 311

Contents xiii

8.9.1 Determining Number of Stages 311

8.9.2 Inlet Flow Rate 312

8.9.3 Compression Power Calculation 313

8.10 Compressor Control 316

8.10.1 Reciprocating Compressors 317

8.10.2 Centrifugal Compressors 317

8.11 Compressor Performance Maps 319

8.11.1 Reciprocating Compressors 319

8.11.2 Centrifugal Compressors 320

References 321

9 Natural Gas Dehydration 323

9.1 Introduction 323

9.2 Water Content Determination 324

9.3 Glycol Dehydration 325

9.3.1 Process Description 328

9.3.2 Design Considerations 330

9.3.3 Operational Problems 341

9.4 Solid Desiccant Dehydration 346

9.4.1 Desiccant Capacity 347

9.4.2 Desiccant Selection 347

9.4.3 Process Description 350

9.4.4 Design Considerations 353

9.4.5 Operational Problems 358

References 361

10 Natural Gas Liquids Recovery 365

10.1 Introduction 365

10.2 NGL Recovery Processes 366

10.2.1 Refrigeration Processes 366

10.2.2 Lean Oil Absorption 376

10.2.3 Solid Bed Adsorption 377

10.2.4 Membrane Separation Process 379

10.2.5 Selection of NGL Recovery Processes 380

10.3 NGL Fractionation 381

10.3.1 Fractionator Operation 383

10.3.2 Types of Fractionators 385

10.3.3 Fractionator Design 386

10.3.4 Design Procedure 395

10.4 Gasoline and LPG Treating 396

10.4.1 Doctor Sweetening Process 397

xiv Contents

10.4.2 Merox Process 397

References 398

11 Sales Gas Transmission 401

11.1 Introduction 401

11.2 Gas Flow Fundamentals 401

11.2.1 General Flow Equation 402

11.2.2 Friction Factor Correlations 403

11.2.3 Practical Flow Equations 407

11.3 Predicting Gas Temperature Profile 409

11.4 Transient Flow in Gas Transmission Pipelines 414

11.5 Compressor Stations and Associated Pipeline

Installations 415

11.5.1 Compressor Drivers 416

11.5.2 Compressors Configurations 417

11.5.3 Reduction and Metering Stations 417

11.6 Design Considerations of Sales Gas Pipelines 418

11.6.1 Line Sizing Criteria 418

11.6.2 Compressor Station Spacing 421

11.6.3 Compression Power 425

11.7 Pipeline Operations 425

References 428

12 Gas Processing Plant Controls and Automation 431

12.1 Introduction 431

12.2 Early Methods of Gas Plant Automation 432

12.3 Microprocessor-Based Automation 433

12.3.1 Programmable Logic Controllers (PLC) 433

12.3.2 Distributed Control Systems (DCS) 433

12.3.3 Standards and Protocols 435

12.4 Control of Equipment and Process Systems 436

12.4.1 Gas Gathering 436

12.4.2 Gas Treating 437

12.4.3 Sulfur Recovery 438

12.4.4 Gas Dehydration 438

12.4.5 Liquids Recovery 440

12.4.6 NGL Fractionation 442

12.4.7 Centrifugal Compressors 443

12.4.8 Centrifugal Pumps 444

12.4.9 Reciprocating Pumps 444

12.4.10 Utilities 444

12.5 Automation Applications 445

12.5.1 Data Historians 445

12.5.2 Asset and Performance Management 446

12.5.3 Statistical Process Control 447

12.5.4 Advanced Regulatory Control 448

12.5.5 Multivariable Predictive Control 448

12.5.6 Optimization 450

12.5.7 Leveraging Automation 452

12.6 Condensate Stabilizer Case Study 455

References 458

Suggested Reading 459

13 Dynamic Simulation of Gas Processing Plants 461

13.1 Introduction 461

13.2 Areas of Application of Dynamic Simulation 462

13.2.1 Plant Design 462

13.2.2 Plant Operation 465

13.3 Modeling Considerations 468

13.3.1 Level of Detail in the Model 468

13.3.2 Model Speed 469

13.3.3 Equipment-Specific Considerations 470

13.4 Control of Equipment and Process Systems 472

13.4.1 Gas Gathering and Transportation 473

13.4.2 Gas Treating 473

13.4.3 Sulfur Recovery 473

13.4.4 Gas Dehydration 473

13.4.5 Liquids Recovery, Natural Gas Liquefaction 474

13.4.6 NGL Fractionation 474

13.5 Case Study I: Analysis of a Fuel Gas System Start-up 474

13.5.1 Introduction 475

13.5.2 Steady-State Analysis 476

13.5.3 Dynamic Analysis 476

13.5.4 Conclusion 477

13.6 Case Study II: Online Dynamic Model of a Trunk Pipeline 478

References 482

Suggested Reading 483

14 Environmental Aspects of Gas Processing and Use 485

14.1 Introduction 485

14.2 Environmental Impacts of Natural Gas Processing 486

14.2.1 Air Pollutant Emissions 486

14.2.2 Gas Flaring Emissions 490

14.2.3 Methane Emissions 492

14.2.4 Water Pollution 496

14.2.5 Soil Pollution 497

14.2.6 Pollution Prevention 497

14.3 Emissions from Natural Gas Use 498

14.3.1 Combustion Emissions 498

14.3.2 Acid Rain Formation 500

14.3.3 Smog Formation 500

14.3.4 Greenhouse Gas Emissions 501

14.3.5 Industrial and Electric Generation Emissions 502

14.4 Protocols and Environmental Programs 503

14.5 Environmental Management System 504

References 505

15 Maximizing Profitability of Gas Plant Assets 507

15.1 Introduction 507

15.2 The Performance Strategy: Integrated Gas Plant 509

15.3 Strategies for Organizational Behavior and Information 510

15.4 Organizational Behavior Model 510

15.4.1 Information Quality 511

15.4.2 Perception of Information 513

15.4.3 Capability to Perform 515

15.4.4 Organizational Hierarchy of Needs 518

15.4.5 Behavior 520

15.5 The Successful Information Strategy 520

15.6 The Impact of Living with Information Technology 521

15.7 Vision of the Modern Plant Operation 523

15.8 Operations Strategy 524

15.9 Model Based Asset Management 525

15.10 Optimization 526

15.10.1 Tools for Optimization 527

15.10.2 Optimization Alternatives 527

15.11 Industrial Relevance 530

15.12 The Technology Integration Challenge 531

15.13 Scientific Approach 532

15.14 Other Miscellaneous Initiatives 533

15.15 Conclusion 534

References 536

Suggested Reading 537

16 Gas Plant Project Management 539

16.1 Introduction 539

16.2 Project Management Overview 540

16.3 Industry Perspective 540

16.4 The Project Management Process 541

16.4.1 Defining Business and Project Objectives 543

16.4.2 Contracting Strategy 545

16.4.3 Conceptual Estimates and Schedules 546

16.4.4 Project Execution Planning 549

16.4.5 Pre Project Planning Measurement 550

16.4.6 The Responsibility Matrix 550

16.5 Project Controls 551

16.5.1 Project Time Line 551

16.5.2 Risk Management 552

16.6 Quality Assurance 562

16.7 Commissioning and Start-up 564

16.8 Operate and Evaluate 565

16.9 Project Closeout 565

16.10 Conclusion 566

References 567

Suggested Reading 567

Appendix 1 Three-Phase Flash Calculation for Hydrocarbon

Systems Containing Water 569

Appendix 2 Conversion Factors 577

Appendix 3 Physical Properties of Fluids 579

Glossary and Acronyms 593

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

Không có nhận xét nào: