EBOOK - Troubleshooting and Repairing Diesel Engines - Fourth Edition (Paul Dempsey)

EBOOK - Khắc phục sự cố và sửa chữa động cơ Diesel - 4th (Paul Dempsey) - 408 Trang.

There are several areas that have changed drastically during the last few years with diesel engines and will greatly affect the near future of diesel engine technologies. The highway trucking industry was the first to require these changes to meet federal EPA emissions guidelines for diesel engines back in the late 1980s. In the mid-1990s these same guidelines were required of the off-highway heavy equipment industry. Now even areas not affected in the past such as the marine, petroleum, and agricultural industries have come under these new requirements. They will change these industries in the same way they have previously changed the trucking and heavy equipment industries. During the last 20 years only certain engine horsepower sizes or industries have come under these federal guidelines. However, the 2007, 2010, and 2012 emissions guidelines will cover and affect all horsepower sizes and industries. Additionally, in most areas the current technologies to meet the 2007 guidelines will not completely meet the 2010 and 2012 requirements without additional technological changes or improvements.

These technological changes are inevitable and future technician training needs will be a reality. This is where diesel engine course books like Troubleshooting and Repairing Diesel Enginescan help the technician stay current with these changing technologies. To show how rapidly these changes have taken place, information of some past and current examples of those areas affected are mentioned.

Since the inception of the EPA guidelines for diesel engines back in the 1980s, most major engine manufacturers have meant the following reductions. Engine particulates have been reduced by 90% and nitrous oxides by nearly 70%. Added to the equation in the 1990s was noise pollution, with reductions required in engine noise levels from 83 to 80 decibels. Although this doesn’t seem like much, it is equal to a 50% noise energy reduction. Add to that the effects of the reduction in fuel sulfur in diesel fuels from 5% to 0.5% to 0.05% (in ppm, 5000 to 500 to 50). Sulfur being the lubricating element in diesel fuels has required many changes to fuel system components.

CONTENTS:

1 Rudolf Diesel 1

2 Diesel basics 9

Compression ratio 9

Induction 12

Ignition and combustion 13

Two- and four-stroke-cycle 15

Power and torque 18

Fuel efficiency 18

Weight 19

Durability 19

Conventional fuels 20

3 Engine installation 23

Trucks and other motor vehicles 23

Stationary engines 26

Marine engines 30

4 Basic troubleshooting 39

Malfunctions 40

Tests 42

Air inlet system 50

Glow plugs 53

Exhaust backpressure 54

Engine mechanical 54

For more information about this title, click here

5 Mechanical fuel systems 61

Air blast 61

Early common-rail 61

Jerk pump system 62

Inline pumps 63

Distributor pumps 67

Delivery valves 74

Injectors 76

Timers 79

Diaphragm controls 81

Centrifugal governors 81

Pneumatic governors 85

Unit injection 87

Low-pressure system 90

Fuel filters and water separators 92

6 Electronic management systems 95

Background 95

Analog versus digital 100

Bosch CAN bus 101

On-board computer 102

Tools 107

Troubleshooting 108

Caterpillar EMS 111

Ford (International) 7.3L DI power stroke 124

Detroit Diesel 129

7 Cylinder heads and valves 139

Combustion chamber types 140

Valve configuration 144

Before you begin 147

8 Engine mechanics 177

Scope of work 177

Diagnosis 179

Rigging 179

Special considerations 181

Cleaning 188

Teardown 189

Lubrication system 189

Filters 195

Block casting 204

Pistons 217

Connecting rods 226

viii Contents

Crankshafts 233

Camshafts and related parts 237

Harmonic balancers 239

Crankshaft bearings 239

Assembly—major components 241

9 Air systems 255

Air cleaners 255

Construction 255

Turbochargers 258

Applications 261

Construction 262

Variable geometry turbine 271

10 Electrical fundamentals 273

Electrons 273

Circuits 274

Electrical measurements 277

Ohm’s law 278

Direct and alternating current 280

Magnetism 283

Electromagnets 284

Voltage sources 285

Generator principles 285

dc motors 289

Storage batteries 292

Switches 294

Solid-state components 299

11 Starting and generating systems 301

Starting aids 302

Wiring 303

Starter circuits 304

Solenoids 318

Starter drives 321

Charging systems 322

Voltage regulation 331

Solid-state regulators 332

Batteries 332

12 Cooling systems 339

Air cooling 339

Liquid cooling 341

13 Greener diesels 359

Brazil 359

U.S. and Europe 361

DIY FAME 363

Straight vegetable oil 363

Dual-fuel engines 365

Conventional fuel 366

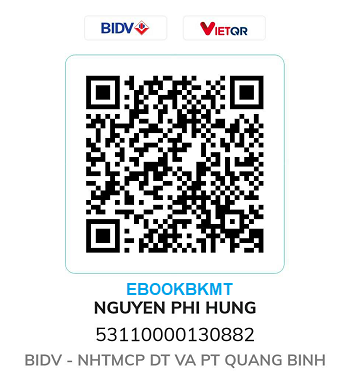

LINK DOWNLOAD

EBOOK - Khắc phục sự cố và sửa chữa động cơ Diesel - 4th (Paul Dempsey) - 408 Trang.

There are several areas that have changed drastically during the last few years with diesel engines and will greatly affect the near future of diesel engine technologies. The highway trucking industry was the first to require these changes to meet federal EPA emissions guidelines for diesel engines back in the late 1980s. In the mid-1990s these same guidelines were required of the off-highway heavy equipment industry. Now even areas not affected in the past such as the marine, petroleum, and agricultural industries have come under these new requirements. They will change these industries in the same way they have previously changed the trucking and heavy equipment industries. During the last 20 years only certain engine horsepower sizes or industries have come under these federal guidelines. However, the 2007, 2010, and 2012 emissions guidelines will cover and affect all horsepower sizes and industries. Additionally, in most areas the current technologies to meet the 2007 guidelines will not completely meet the 2010 and 2012 requirements without additional technological changes or improvements.

These technological changes are inevitable and future technician training needs will be a reality. This is where diesel engine course books like Troubleshooting and Repairing Diesel Enginescan help the technician stay current with these changing technologies. To show how rapidly these changes have taken place, information of some past and current examples of those areas affected are mentioned.

Since the inception of the EPA guidelines for diesel engines back in the 1980s, most major engine manufacturers have meant the following reductions. Engine particulates have been reduced by 90% and nitrous oxides by nearly 70%. Added to the equation in the 1990s was noise pollution, with reductions required in engine noise levels from 83 to 80 decibels. Although this doesn’t seem like much, it is equal to a 50% noise energy reduction. Add to that the effects of the reduction in fuel sulfur in diesel fuels from 5% to 0.5% to 0.05% (in ppm, 5000 to 500 to 50). Sulfur being the lubricating element in diesel fuels has required many changes to fuel system components.

CONTENTS:

1 Rudolf Diesel 1

2 Diesel basics 9

Compression ratio 9

Induction 12

Ignition and combustion 13

Two- and four-stroke-cycle 15

Power and torque 18

Fuel efficiency 18

Weight 19

Durability 19

Conventional fuels 20

3 Engine installation 23

Trucks and other motor vehicles 23

Stationary engines 26

Marine engines 30

4 Basic troubleshooting 39

Malfunctions 40

Tests 42

Air inlet system 50

Glow plugs 53

Exhaust backpressure 54

Engine mechanical 54

For more information about this title, click here

5 Mechanical fuel systems 61

Air blast 61

Early common-rail 61

Jerk pump system 62

Inline pumps 63

Distributor pumps 67

Delivery valves 74

Injectors 76

Timers 79

Diaphragm controls 81

Centrifugal governors 81

Pneumatic governors 85

Unit injection 87

Low-pressure system 90

Fuel filters and water separators 92

6 Electronic management systems 95

Background 95

Analog versus digital 100

Bosch CAN bus 101

On-board computer 102

Tools 107

Troubleshooting 108

Caterpillar EMS 111

Ford (International) 7.3L DI power stroke 124

Detroit Diesel 129

7 Cylinder heads and valves 139

Combustion chamber types 140

Valve configuration 144

Before you begin 147

8 Engine mechanics 177

Scope of work 177

Diagnosis 179

Rigging 179

Special considerations 181

Cleaning 188

Teardown 189

Lubrication system 189

Filters 195

Block casting 204

Pistons 217

Connecting rods 226

viii Contents

Crankshafts 233

Camshafts and related parts 237

Harmonic balancers 239

Crankshaft bearings 239

Assembly—major components 241

9 Air systems 255

Air cleaners 255

Construction 255

Turbochargers 258

Applications 261

Construction 262

Variable geometry turbine 271

10 Electrical fundamentals 273

Electrons 273

Circuits 274

Electrical measurements 277

Ohm’s law 278

Direct and alternating current 280

Magnetism 283

Electromagnets 284

Voltage sources 285

Generator principles 285

dc motors 289

Storage batteries 292

Switches 294

Solid-state components 299

11 Starting and generating systems 301

Starting aids 302

Wiring 303

Starter circuits 304

Solenoids 318

Starter drives 321

Charging systems 322

Voltage regulation 331

Solid-state regulators 332

Batteries 332

12 Cooling systems 339

Air cooling 339

Liquid cooling 341

13 Greener diesels 359

Brazil 359

U.S. and Europe 361

DIY FAME 363

Straight vegetable oil 363

Dual-fuel engines 365

Conventional fuel 366

LINK DOWNLOAD

%20(1).png)

.png)

%20(1)%20(1).png.png)

%20(1).png)

Không có nhận xét nào: